LOU from WI

Member

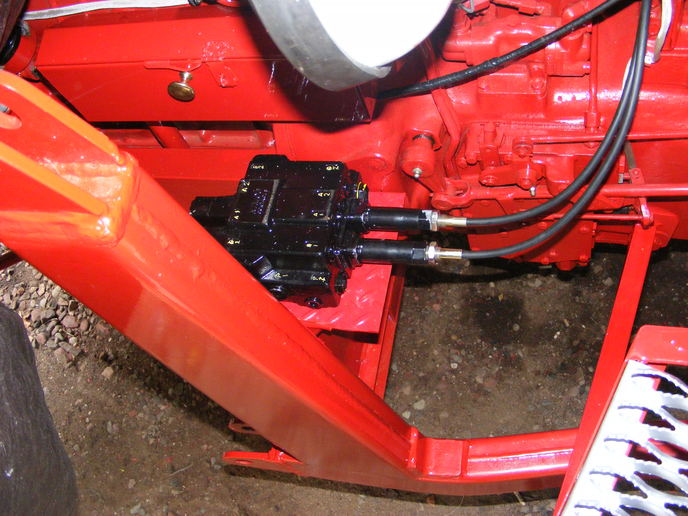

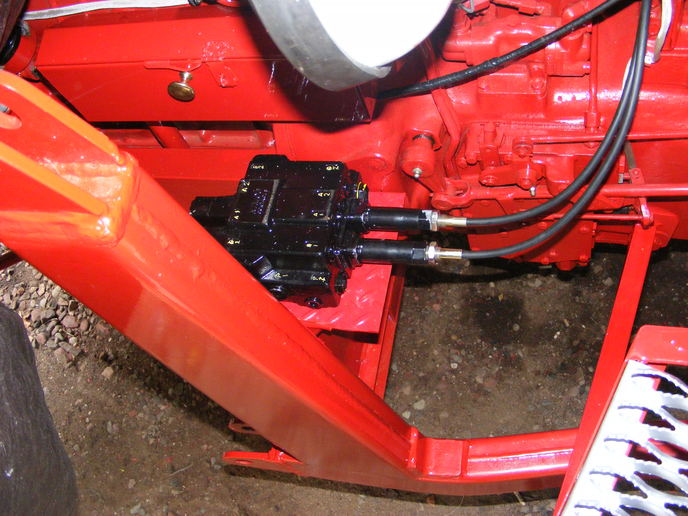

Well People,Guess what?Westendorf Has trade secrets they won"t tell ya (Hydraulic Steel tubing wall thickness and OD of hydraulic tubing for loader cylinder. ) .Guess that would destroy national security documents. What A joke that was. Any way we got the information from ALAMO LOADERS. If they (Westendorf CO) were the only loader Mfg Co.WE wouldnt purchase one from them. So disrespectfull ,curt.over the phone. Nasty Nasty. We"re re-doing the Hydraulics on a Schwartz loader so needed the information to enable us to do the majority of the lines in Stainless steel tubing. Got the valve assembly on(left side) a mounting plate, and hooked up to the Joy stick with out the hyd Valves inside the cab. Seen em inside the cab and from all we have looked at, They LEAK SOMETHING FIERCE. Hys fluid all over the inside panels ,floor,and the upholstery. Others we looked at has a multitude of rubber lines stuck out all over the tractor, loader, hanging down underneath and just waiting to give way to the elements.They wear through the outer wall of the rubber ,(see pics).

We plan on using S.Steel tubing 5/8 od,.065 wall thickness. Wondering the best install of Hyd fittings ,Flare,or ferrel? Got the S.Steel comming but have to travel 2 hrs one way.

Dont mind that at all. Looking up prices of hyd fittings ,both flare & ferrel. Trying to decide which is the best for reliability & strength.

Sending pictures of the Joy Stick and Valve,

along with a tractor at the dealers that described the botched up Hyd lines we seen.

ANY SUGGESTIONS ON USING FLARED OR FERRELLS? Would appreciate imputs!!!!

Thanks .

LOU

We plan on using S.Steel tubing 5/8 od,.065 wall thickness. Wondering the best install of Hyd fittings ,Flare,or ferrel? Got the S.Steel comming but have to travel 2 hrs one way.

Dont mind that at all. Looking up prices of hyd fittings ,both flare & ferrel. Trying to decide which is the best for reliability & strength.

Sending pictures of the Joy Stick and Valve,

along with a tractor at the dealers that described the botched up Hyd lines we seen.

ANY SUGGESTIONS ON USING FLARED OR FERRELLS? Would appreciate imputs!!!!

Thanks .

LOU