stevieb49829

Well-known Member

- Location

- Spirit Lake, Idaho

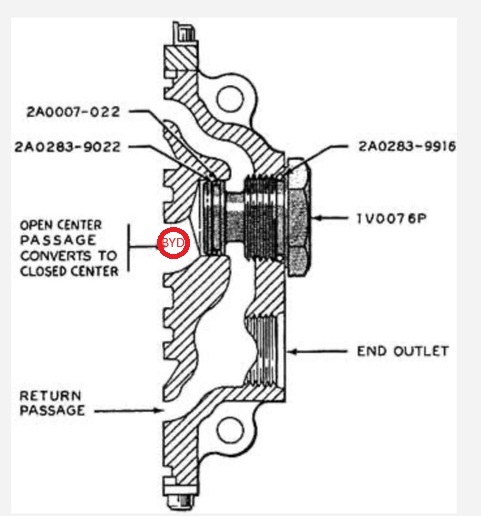

Back in October, I got help from folks on my loader hydraulics power beyond capabilities. I took the advice and added the plug that converted my loader valve to power beyond, and now my 3 point works like it should. However, the plug was advertised as converting my valve to closed center. After some heavy duty thinking, it made sense. The plug plugs off normal return to tank. At that point the flow is stopped and can go nowhere, but in my case, it now follows the hose off the BYD port, straight to my second valve that runs the 3 point. But it begs the question: where does the flow go on a closed center system? Thanks again, and again, and again for all your knowledge and help. steve