farmallboy15

Member

How critical is a little bit of cylinder wall scoring?

I have a little 2 cylinder Mitsubishi diesel that I got non-running. After some tinkering, it ran fairly well but was terribly hard to start and had awful blow-by. Tested compression and cylinder 2 had acceptable pressure, cylinder 1 was down to 300PSI (~100psi lower than #2). Upon tear down both cylinders had busted oil control rings. #1 had a cracked piston to boot.

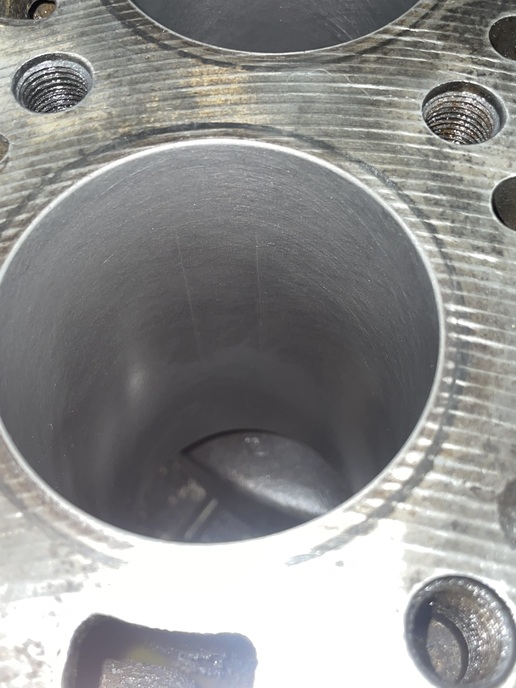

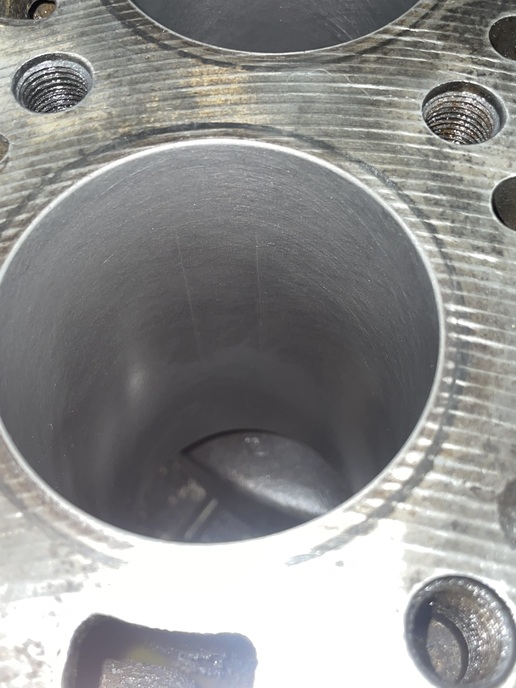

When the rings busted they left scores on the cylinder walls. #2 cleaned up pretty easy with a hone. #1 still shows some marks. Is it critical to get it bored and the score marks removed or for low hp, low rpm and low use, should I just run it?

I have a little 2 cylinder Mitsubishi diesel that I got non-running. After some tinkering, it ran fairly well but was terribly hard to start and had awful blow-by. Tested compression and cylinder 2 had acceptable pressure, cylinder 1 was down to 300PSI (~100psi lower than #2). Upon tear down both cylinders had busted oil control rings. #1 had a cracked piston to boot.

When the rings busted they left scores on the cylinder walls. #2 cleaned up pretty easy with a hone. #1 still shows some marks. Is it critical to get it bored and the score marks removed or for low hp, low rpm and low use, should I just run it?