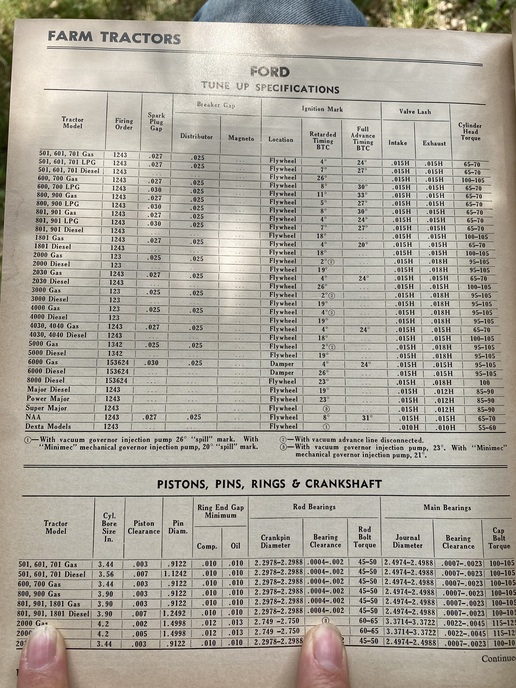

looking for info on my ford 850 build, doing a complete rebuild on 1955 850 with 172 gas engine. ordered new crank, 4.0 overbore pistons and sleeves, when installing crank, main bearings (std) have right at .002 clearance which seems perfect but the rod bearings (std) are between .001 and .0015 when torqued to 45 ft pounds picture included. looking for what others think about this clearance. I talked to yesterdays tractor parts where all parts were purchased and they confirmed the correct crankshaft sent. opinions on the rod bearing clearance please.

Untitled URL Link

Untitled URL Link