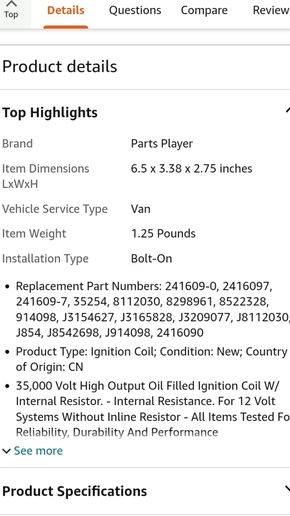

I just picked up a case vac wide front that has been converted to 12 volt at one point but has sitting in a field with the exhaust uncovered since 2016 when i was told it supposedly last ran before they took the coil off of it for another machine. I plan on getting it running and fixing any issues it might have and repainting it. What should i try to do to start on getting it running because it is missing the coil and a few other things. I also have no idea on how the hydraulics on it work or function and if they do work or function at all. Any help or tips on getting it running would be appreciated.