[email protected]

New User

thanks to all the great help and comments i got here when i started this project a little while back i have gotten it kind of stripped down. now just trying to get it clean enough to see if i can get a little fresh paint on it before re-assembly begins.

i have found a rebuilt short block and had the head rebuilt at a local machine shop but before we get to that point.

i did not get to use this machine only to start the motor and hear it banging loudly, the rod bearing on the crank shaft for center cylinder was completely gone, no parts found in oil pan.

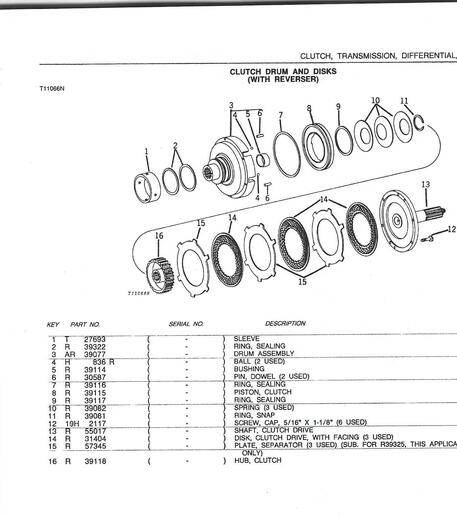

i will be inspecting with my limited knowledge all components looking for obvious issues. maybe i should consider a clutch and brakes while i'm where i'm at? rebuild hydraulic pump?

anyone with more knowledge of these things, i would be very grateful for any comments or suggestions on what to look for / at while i'm cleaning and painting? i already see some funny look pin holes at some hydraulic ram connections. but i think at this point i'm most concerned with mechanicals.

thanks much

i have found a rebuilt short block and had the head rebuilt at a local machine shop but before we get to that point.

i did not get to use this machine only to start the motor and hear it banging loudly, the rod bearing on the crank shaft for center cylinder was completely gone, no parts found in oil pan.

i will be inspecting with my limited knowledge all components looking for obvious issues. maybe i should consider a clutch and brakes while i'm where i'm at? rebuild hydraulic pump?

anyone with more knowledge of these things, i would be very grateful for any comments or suggestions on what to look for / at while i'm cleaning and painting? i already see some funny look pin holes at some hydraulic ram connections. but i think at this point i'm most concerned with mechanicals.

thanks much