Geo-TH,In

Well-known Member

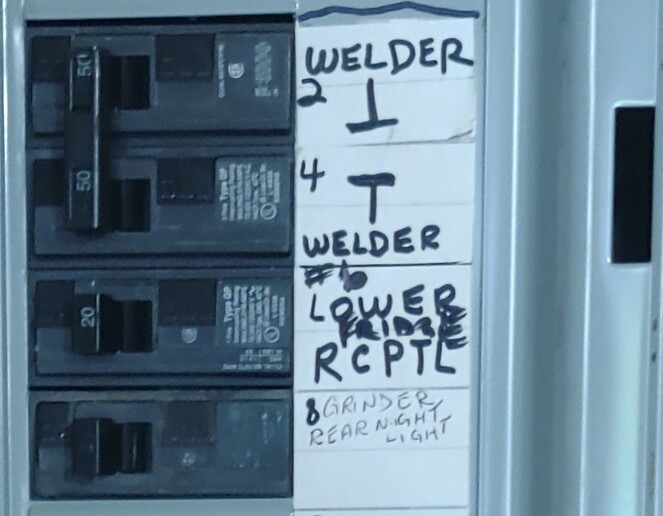

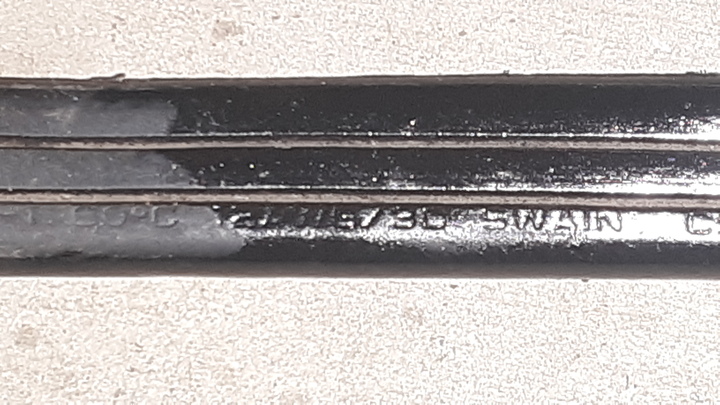

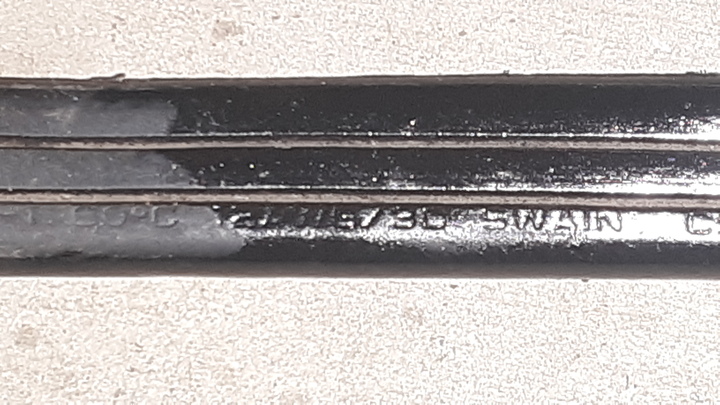

If not someone should tell Lincoln not to use 12g wire attached to a 50 amp plug.

I'm sure there is some excuse Lincoln can use 20 amp wire in a 50 amp welder.

The gray wire goes To a clothes dryer.

10g wire.

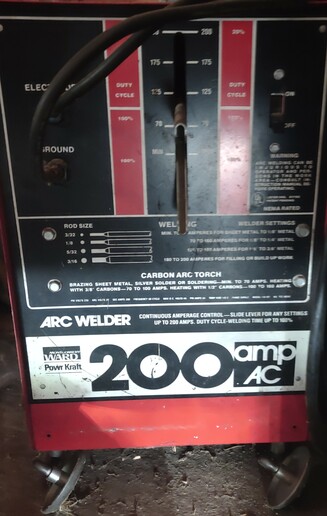

What guage copper measures 3/16 ?

This is what 225 amp Lincoln uses for welding cables.

How many amps can 3/16 copper wire handle if you are going by CODE?,

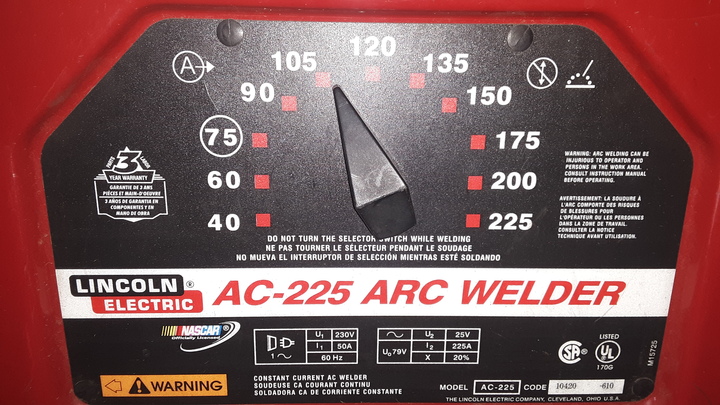

I only use 105 amps to weld 1/8 rods.

I don't weld thick metals.

I may go to 120 or 135 setting to warm up the rod and metal for a very short time.

That us to hot for a 1/8 rod.

When I get someone to watch the amprobes when I'm welding. I would like a know what the prime and secondary currents are at the 105 amp setting.

I've been using 10g wire and 30 amp breaker forever on my 12g Lincoln and see no signs of heat stress on the 10 or 12g wire.

I don't attempt to weld half inch metal.

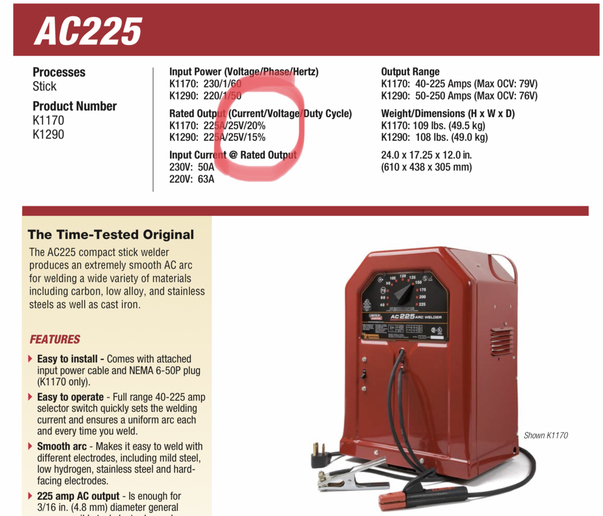

Can someone post a link to the Lincoln's duty cycle?

If I recall the welder is not a commercial grade welder..

Duty cycle decrease greatly at full amps.

Someday I'll like to open the welder and see what guage wire is used to make the transformer and is it copper?

If you get inside the welder please post pictures and measure wire diameter.

Please post the actual current when you are welding.

I'm sure there is some excuse Lincoln can use 20 amp wire in a 50 amp welder.

The gray wire goes To a clothes dryer.

10g wire.

What guage copper measures 3/16 ?

This is what 225 amp Lincoln uses for welding cables.

How many amps can 3/16 copper wire handle if you are going by CODE?,

I only use 105 amps to weld 1/8 rods.

I don't weld thick metals.

I may go to 120 or 135 setting to warm up the rod and metal for a very short time.

That us to hot for a 1/8 rod.

When I get someone to watch the amprobes when I'm welding. I would like a know what the prime and secondary currents are at the 105 amp setting.

I've been using 10g wire and 30 amp breaker forever on my 12g Lincoln and see no signs of heat stress on the 10 or 12g wire.

I don't attempt to weld half inch metal.

Can someone post a link to the Lincoln's duty cycle?

If I recall the welder is not a commercial grade welder..

Duty cycle decrease greatly at full amps.

Someday I'll like to open the welder and see what guage wire is used to make the transformer and is it copper?

If you get inside the welder please post pictures and measure wire diameter.

Please post the actual current when you are welding.