Geo-TH,In

Well-known Member

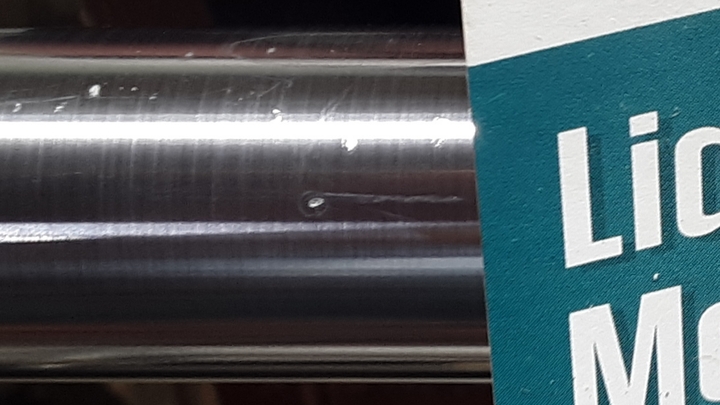

You can feel the imperfections in the rod

better than you can see them.

I used 600g for my final sanding.

I held sandpaper against the rod using the

flat metal tool.

I enlarge this pic.

You can't feel the pits filled with liquid

metal.

Don't get nervous.

All fluid

Returning to the tank must pass through

the hydraulic filter.

I think this will work on my cylinder rods

which were damaged before I bought the

terramite.

I've tried epoxy. Doesn't work.

Do you use anything better than permatex

liquid metal?

I let the liquid metal cure for a week

before sanding.