1939farmall

Member

Today we continue work on the 648. Started to clean up the gas tank and found a couple of holes in the bottom. A good friend of ours was able to patch it.

We tested it and had no leaks! Next order of business was the bad tire. Its completely rotten. Wont stay on the rim.

The old one came right off the new one was a bit of a pain. But we eventually got it on the rim and aired up.

Since the gas tank was out of the way we decided to check out the rear end.

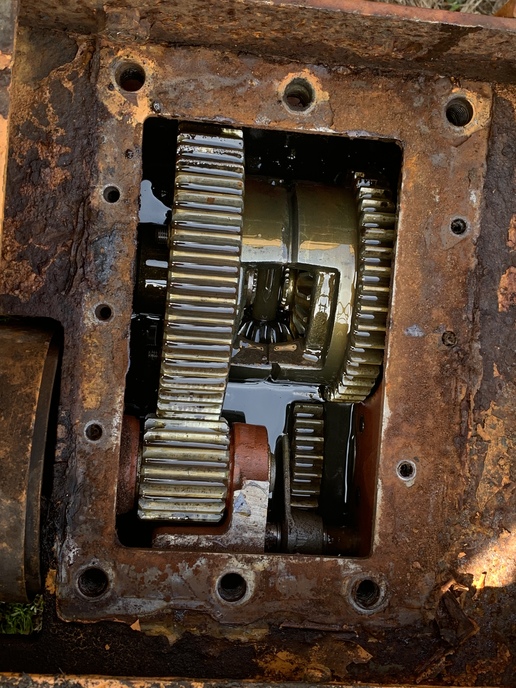

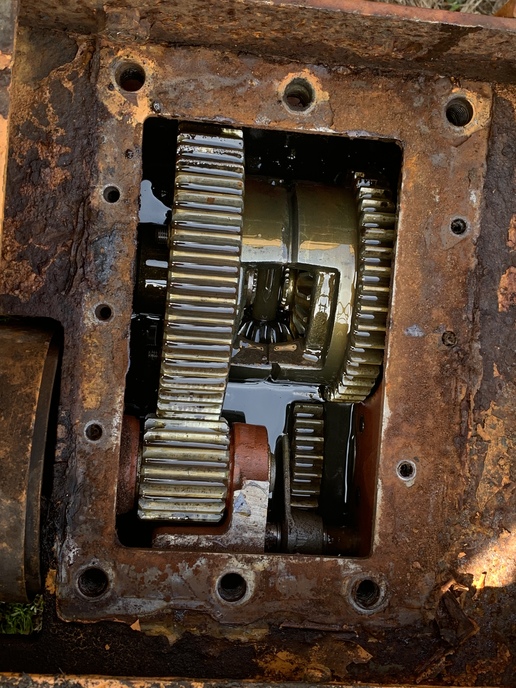

The picture doesnt show it but I do have cribbing under the tractor to brace it. The differential cover bolts also hole the transaxle on the machine so I wanted to be sure nothing could move.

The outside looked so rough, I didnt hold much hope for what we would find on the inside. I expected an 80WT milkshake for sure! To my surprise someone had been in the rear end before us. It looked great! No chipped gear teeth, no water, good bolts holding the differential together!

So we changed the oil, cleaned all the surfaces and closed it up. I spray painted the the patch on the tank and the differential cover since there no access to them with the tractor assembled. We reassembled it with a different operators seat. The original was falling apart. This is the first time this machine has sat on 4 aired up tires in who knows how long! I decided to try to move it into the shop for tonight since they are calling for storms here overnight.

This is the first time its really moved under its own power in at least 10 years! But it still has some issues. It can hardly move when in high. I was able to drive it on flat ground and maneuver in the shop with it in low. I really didnt like having to leave the bucket up like that but its the only way I could get the garage door shut for the night. Thats why I have the pipe under it to hold it up just in case. The tractor is driven with a hydraulic motor. The oil in the system is low and looks milky. I think the next item will be to drain the hydraulic system and get some good oil in it and a new filter. If that doesnt help I guess the only other thing to do is to try to adjust the linkages. That where we stand tonight. Everything seems to moving along. Anybody got some good tips on draining this system drained? As alway thanks for your comments and thoughts, we appreciate it!

We tested it and had no leaks! Next order of business was the bad tire. Its completely rotten. Wont stay on the rim.

The old one came right off the new one was a bit of a pain. But we eventually got it on the rim and aired up.

Since the gas tank was out of the way we decided to check out the rear end.

The picture doesnt show it but I do have cribbing under the tractor to brace it. The differential cover bolts also hole the transaxle on the machine so I wanted to be sure nothing could move.

The outside looked so rough, I didnt hold much hope for what we would find on the inside. I expected an 80WT milkshake for sure! To my surprise someone had been in the rear end before us. It looked great! No chipped gear teeth, no water, good bolts holding the differential together!

So we changed the oil, cleaned all the surfaces and closed it up. I spray painted the the patch on the tank and the differential cover since there no access to them with the tractor assembled. We reassembled it with a different operators seat. The original was falling apart. This is the first time this machine has sat on 4 aired up tires in who knows how long! I decided to try to move it into the shop for tonight since they are calling for storms here overnight.

This is the first time its really moved under its own power in at least 10 years! But it still has some issues. It can hardly move when in high. I was able to drive it on flat ground and maneuver in the shop with it in low. I really didnt like having to leave the bucket up like that but its the only way I could get the garage door shut for the night. Thats why I have the pipe under it to hold it up just in case. The tractor is driven with a hydraulic motor. The oil in the system is low and looks milky. I think the next item will be to drain the hydraulic system and get some good oil in it and a new filter. If that doesnt help I guess the only other thing to do is to try to adjust the linkages. That where we stand tonight. Everything seems to moving along. Anybody got some good tips on draining this system drained? As alway thanks for your comments and thoughts, we appreciate it!