1939farmall

Member

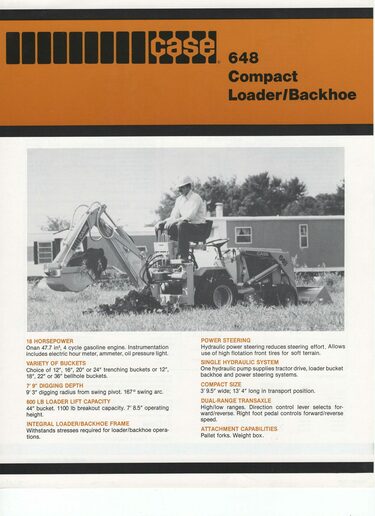

We spend most of today working on the little case. Just to recap Im the new owner and was told it hasnt run in 10 years.

We cleaned out the carburetor, what a mess! I believe its been 10 years!

Son had absolute confidence it would run, I had my doubts. He kept saying once we get it running. I kept saying if we get it running. Then he said of course its gonna run were the ones working on it! Thats exactly how his grandfather was, no doubt in his mind it wouldnt work.

We let the cylinders soak for a week in ATF just to make sure the rings were loose and give it a little lubrication. Test 1 was for compression. It does. Test 2 was for spark. It does. Changed the oil and filter and fed it fuel from a temporary tank. It started so quick it took us both by surprise!

The Onan engine runs really smooth. We just couldnt help ourselves, we had to try it out!

Now that we know it functions we can continue down our list of things it needs. Were having trouble feeding it enough gas to keep it running so we may need a new pump. We need to clean the gas tank up. Rewire the electric system. 1 tire for sure. The sun baked it for all this time its rotten. And I think the drive linkage will need to be adjusted. Its hard to check that with the temp tank on the ground next to it! As always thank you for following along with us and for your thoughts and knowledge! We will update as we continue!

We cleaned out the carburetor, what a mess! I believe its been 10 years!

Son had absolute confidence it would run, I had my doubts. He kept saying once we get it running. I kept saying if we get it running. Then he said of course its gonna run were the ones working on it! Thats exactly how his grandfather was, no doubt in his mind it wouldnt work.

We let the cylinders soak for a week in ATF just to make sure the rings were loose and give it a little lubrication. Test 1 was for compression. It does. Test 2 was for spark. It does. Changed the oil and filter and fed it fuel from a temporary tank. It started so quick it took us both by surprise!

The Onan engine runs really smooth. We just couldnt help ourselves, we had to try it out!

Now that we know it functions we can continue down our list of things it needs. Were having trouble feeding it enough gas to keep it running so we may need a new pump. We need to clean the gas tank up. Rewire the electric system. 1 tire for sure. The sun baked it for all this time its rotten. And I think the drive linkage will need to be adjusted. Its hard to check that with the temp tank on the ground next to it! As always thank you for following along with us and for your thoughts and knowledge! We will update as we continue!