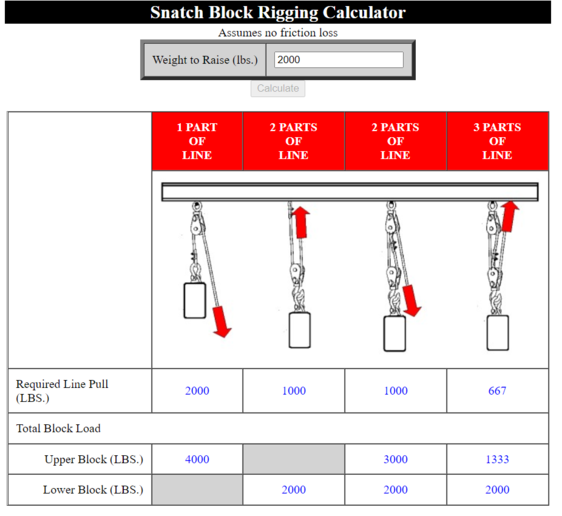

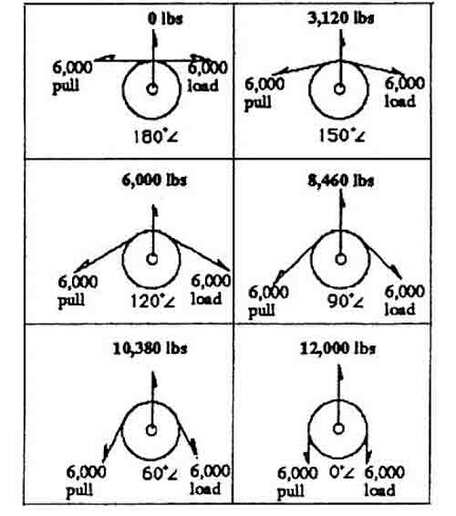

I have a 12000 pound 12 volt electric winch.what would the lifting capacity compared to rolling load be for this winch be?I also use a single snatch block with it to potentially depending on how its rigged double the capacity .I have a 20 ft con-ex container weighing around 7000 pounds I want to load onto a 3plus foot high flatbed trailer.I have done this before but had to jack and block one end up to the trailer height.thinking about installing a roller on the very back of the trailer so

I can suck the container up and onto the trailer

I can suck the container up and onto the trailer