Massey_165

Member

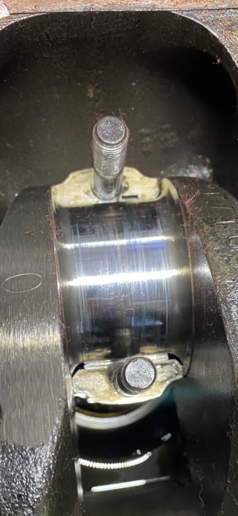

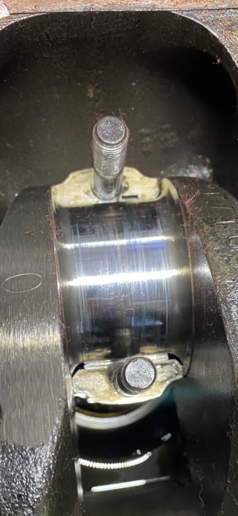

I recently made a post about putting new crank bearings in, Ive got some pictures now.

I have a Massey Ferguson 165 Perkins diesel, the engine is out and upside down on a stand, Id like to just replace the rod bearings without removing the crank, the main bearings are in spec and look good, the rod bearings are out of spec and one is scored, the crank journal has a small ridge I can barely feel about 1/2 around it. Just wondering if I could get by with just new rod bearings, maybe polish the one journal? Pics are added.

Main bearing clearance: .003

Rod bearing clearance: .002

I have a Massey Ferguson 165 Perkins diesel, the engine is out and upside down on a stand, Id like to just replace the rod bearings without removing the crank, the main bearings are in spec and look good, the rod bearings are out of spec and one is scored, the crank journal has a small ridge I can barely feel about 1/2 around it. Just wondering if I could get by with just new rod bearings, maybe polish the one journal? Pics are added.

Main bearing clearance: .003

Rod bearing clearance: .002