white halftrack

Member

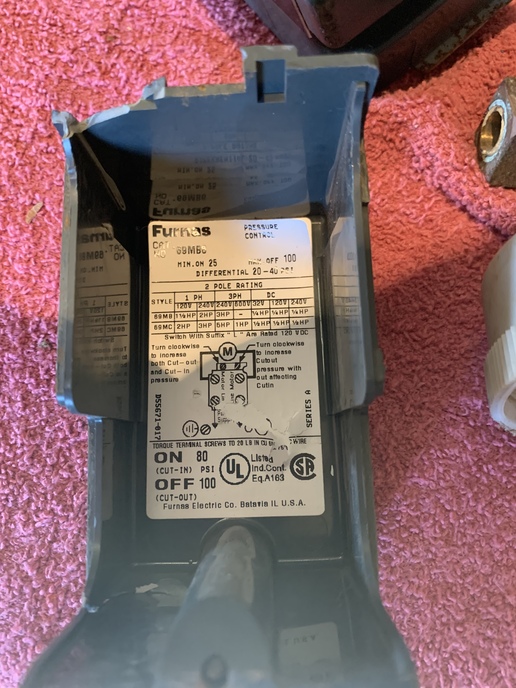

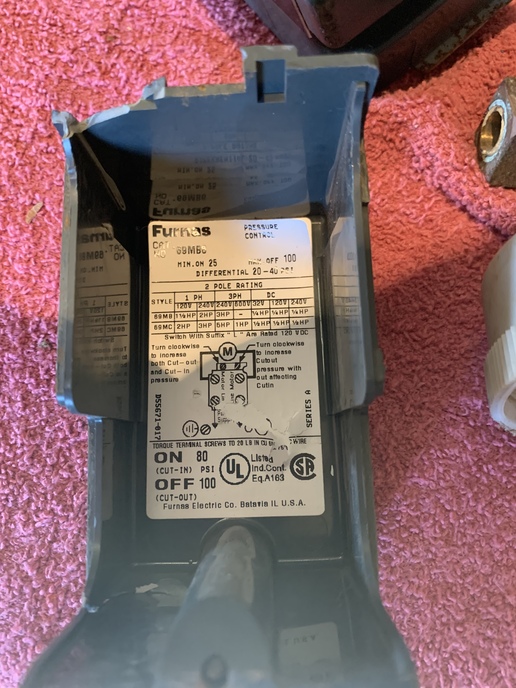

I have a few questions about an air compressor and have had luck with the knowledgeable folk on this forum. If not in the right area I am sorry. We picked up a nice coats tire machine and knew we needed a bigger compressor. We found a larger compressor but have multiple questions. It is an older Speedaire Duplex compressor. I am a bit sketchy on the electrical part of it. Would this compressor run the tire machine?

It is 3 phase and we just have single in our shop. Will these motors run on single phase or be converted? If not with two motors will one Vfd work and what size? Would like to maintain at least 100 psi.

Any help appreciated. The compressor is pretty cheap to obtain.

It is 3 phase and we just have single in our shop. Will these motors run on single phase or be converted? If not with two motors will one Vfd work and what size? Would like to maintain at least 100 psi.

Any help appreciated. The compressor is pretty cheap to obtain.