grandpa Love

Well-known Member

9:30 pm. Been sitting in the living room watching TV with my wife. Been thinking about this tractor. We walked down to the barn. There is zero clearance on any of the valves. Book says check hot,but shouldn't there be some clearance on some of the valves?? The thinnest gauge will not slide in there.

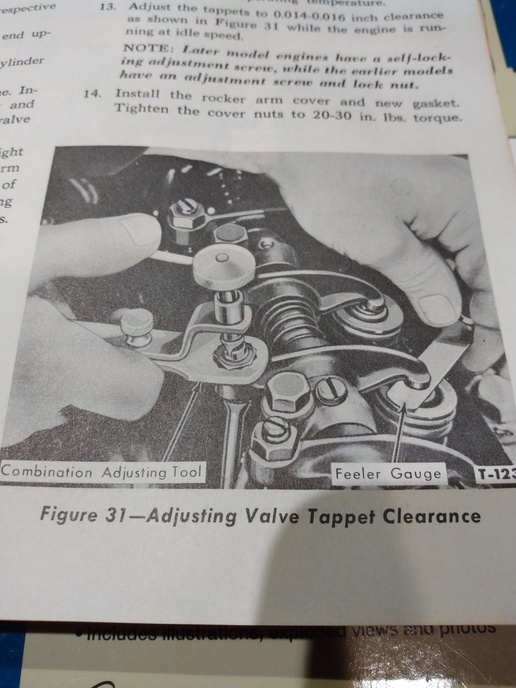

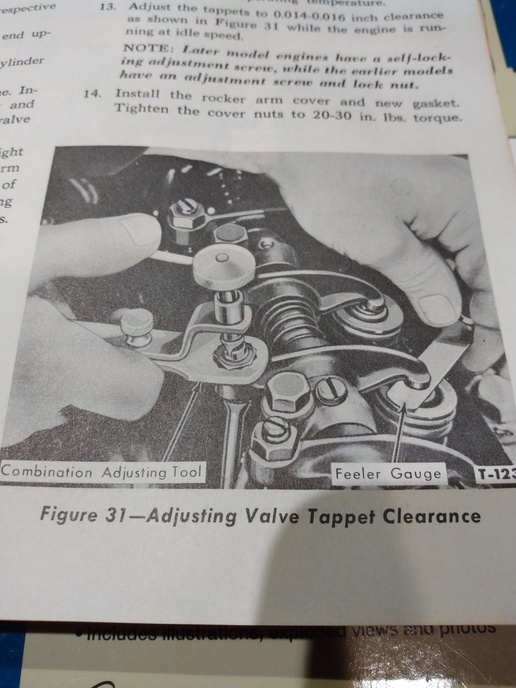

I don't have the combination adjusting tool I'm guessing a wrench will work? They appear to be tightened down within a round of being all the way......

I don't have the combination adjusting tool I'm guessing a wrench will work? They appear to be tightened down within a round of being all the way......