Geo-TH,In

Well-known Member

At 3 o'clock you can see scratches where the rotor rubbed the stator.

I used dremel and diamond burr to removed a little metal from stator.

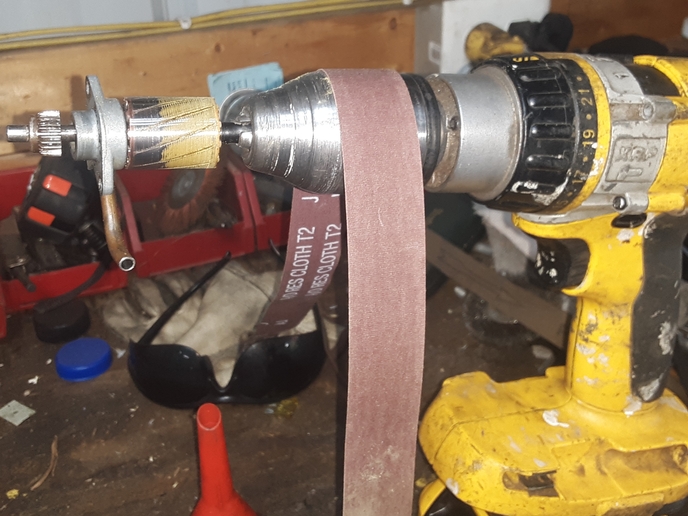

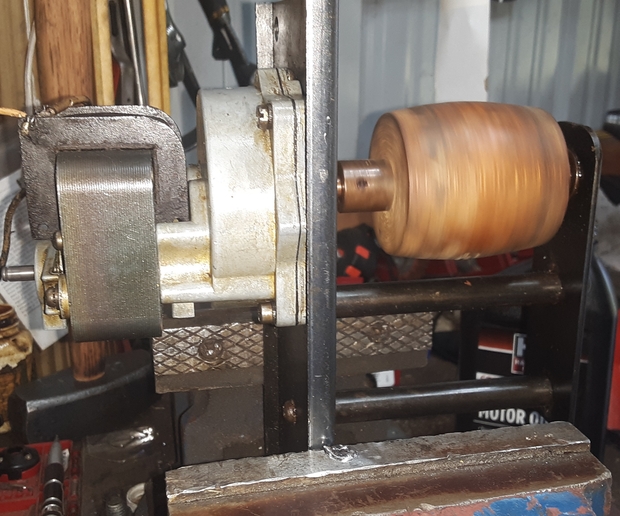

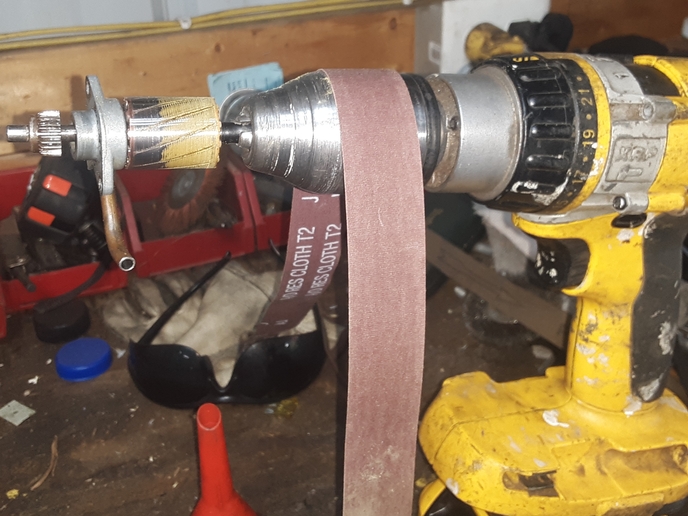

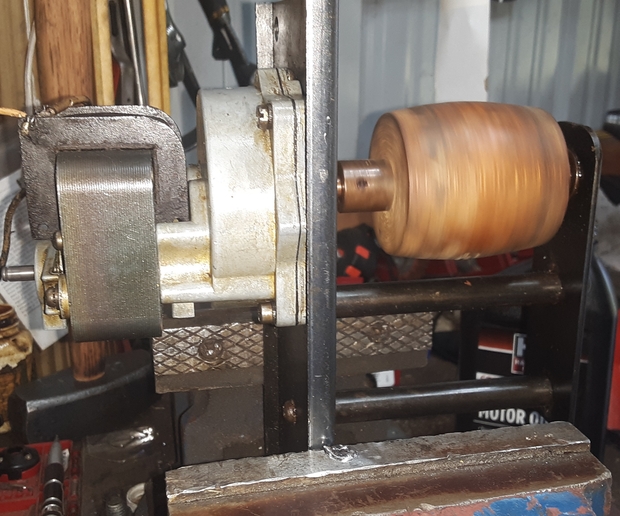

Used my Dewalt lathe, 1/2 inch drill. A energy cloth to polish scratches off rotor. Between sanding and grinding I got lucky. Rotor an stator don't touch

I've got bowling machine before my son was born, over 42 years ago

The lift motor has always been noisy. . I always thought I was a gear noise. Come to find out the motor.

Now I need to stop by a place in town and see if I can get a gizmo to splice the flat belt.

I'm a winner, my grinding sanding fix did the trick

No way to remove the gear on shaft.

Grandkids will be happy.

I used dremel and diamond burr to removed a little metal from stator.

Used my Dewalt lathe, 1/2 inch drill. A energy cloth to polish scratches off rotor. Between sanding and grinding I got lucky. Rotor an stator don't touch

I've got bowling machine before my son was born, over 42 years ago

The lift motor has always been noisy. . I always thought I was a gear noise. Come to find out the motor.

Now I need to stop by a place in town and see if I can get a gizmo to splice the flat belt.

I'm a winner, my grinding sanding fix did the trick

No way to remove the gear on shaft.

Grandkids will be happy.