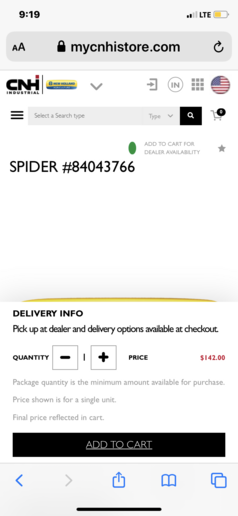

I know this should be on implement alley, but more traffic here . Have a New Holland 479 haybine and am replacing the 2 u joints at the end of the shaft closest to the tractor. Old ones looked original and came out hard. Have 2 new ones from CNH. I cleaned up the yoke for the first with emery cloth and made sure it was clean with no rough spots or burrs. Go to put it together and all it did was bind. The caps wouldnt seat all the way even though the joint moved freely. I did get a little upset and cut out the new joint. I figured I may have gotten one of the needles out of place but that wasnt it. When I got the caps out of the yoke after cutting the u joint it the yoke had ridges where the cap was fighting the yoke to go in. The u joints are from our local Case/IH dealer. Made in the land of almost good. Problem with my yoke or variances in parts ? How to get past it ? I put a very fine wheel on my die grinder to get the cups to sit better . Thoughts ?

- Thread starter 300jk

- Start date

Similar threads

We sell tractor parts! We have the parts you need to repair your tractor - the right parts. Our low prices and years of research make us your best choice when you need parts. Shop Online Today.

Copyright © 1997-2024 Yesterday's Tractor Co.

All Rights Reserved. Reproduction of any part of this website, including design and content, without written permission is strictly prohibited. Trade Marks and Trade Names contained and used in this Website are those of others, and are used in this Website in a descriptive sense to refer to the products of others. Use of this Web site constitutes acceptance of our User Agreement and Privacy Policy TRADEMARK DISCLAIMER: Tradenames and Trademarks referred to within Yesterday's Tractor Co. products and within the Yesterday's Tractor Co. websites are the property of their respective trademark holders. None of these trademark holders are affiliated with Yesterday's Tractor Co., our products, or our website nor are we sponsored by them. John Deere and its logos are the registered trademarks of the John Deere Corporation. Agco, Agco Allis, White, Massey Ferguson and their logos are the registered trademarks of AGCO Corporation. Case, Case-IH, Farmall, International Harvester, New Holland and their logos are registered trademarks of CNH Global N.V.

Yesterday's Tractors - Antique Tractor Headquarters

Website Accessibility Policy