You should upgrade or use an alternative browser.

- Thread starter SVcummins

- Start date

Bob Bancroft

Well-known Member

- Location

- Aurora NY

Ken Loewenhagen

Member

caterpillar guy

Well-known Member

Walston

Member

- Location

- Upstate SC

I usually use this, mostly because it is what my machine shop sells. I have done several engines with it with success.

https://www.amazon.com/Permatex-819...mp;qid=1609244809&sr=8-2&tag=mh0b-20

Walston

Member

- Location

- Upstate SC

This is what I usually use: Permatex 81950 Ultra Slick Engine Assembly Lube. Mostly because it is what my machine shop sells.

https://www.amazon.com/Permatex-81950-Ultra-Engine-Assembly/dp/B000HBNVSK/ref=sr_1_2?dchild=1&hvadid=78065451482226&hvbmt=be&hvdev=c&hvqmt=e&keywords=ultra+slick&qid=1609244809&sr=8-2&tag=mh0b-20

Hobo,NC

Well-known Member

- Location

- Sanford, NC

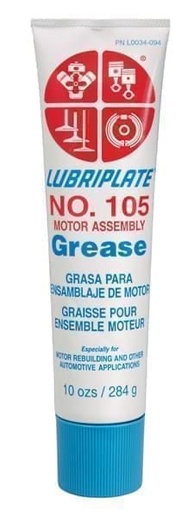

I just did an engine I use Lubriplate in the oil pump and a few other places and a lube like you mentioned. The other lube was federal Mogul #55-400. A good bet it the same as the permatex.

Kansasredneck

Member

J.Wondergem

Well-known Member

- Location

- Rockford, Mi.

Motor oil on everything but the cam, then I use Cam Lube.

casecollectorsc

Well-known Member

- Location

- E central SD.

560Dennis

Well-known Member

- Location

- Madison,Ohio

Phil9N3667

Well-known Member

J Hamilton

Well-known Member

- Location

- Southern Illinois

Goose

Well-known Member

Never had a problem.

In fact, in all the years I raced, we only had two engine failures during a race. One was a fancy double roller racing timing chain. We went back to a plain old Chevy chain and no more timing chain problems.

The other was an engine blew and we put enough of it back together to determine a connecting rod cap bolt had broken. After that, we never torqued rod cap bolts more than twice. We'd install new bolts, reuse them once, and pitch them.

Michael Soldan

Well-known Member

and then fired them up.

Super H Mike

Member

retired farmer

Well-known Member

Gary Mitchell

Well-known Member

Similar threads

We sell tractor parts! We have the parts you need to repair your tractor - the right parts. Our low prices and years of research make us your best choice when you need parts. Shop Online Today.

Copyright © 1997-2024 Yesterday's Tractor Co.

All Rights Reserved. Reproduction of any part of this website, including design and content, without written permission is strictly prohibited. Trade Marks and Trade Names contained and used in this Website are those of others, and are used in this Website in a descriptive sense to refer to the products of others. Use of this Web site constitutes acceptance of our User Agreement and Privacy Policy TRADEMARK DISCLAIMER: Tradenames and Trademarks referred to within Yesterday's Tractor Co. products and within the Yesterday's Tractor Co. websites are the property of their respective trademark holders. None of these trademark holders are affiliated with Yesterday's Tractor Co., our products, or our website nor are we sponsored by them. John Deere and its logos are the registered trademarks of the John Deere Corporation. Agco, Agco Allis, White, Massey Ferguson and their logos are the registered trademarks of AGCO Corporation. Case, Case-IH, Farmall, International Harvester, New Holland and their logos are registered trademarks of CNH Global N.V.

Yesterday's Tractors - Antique Tractor Headquarters

Website Accessibility Policy