I'm getting close to buying a prefab steel building and hoping I'm not making a mistake. There seems to be 100's of companies selling buildings, but most I figure are only brokers. This is a first time purchase for me and not sure I trust any of these companies. The best prices I have so far are from Ithaca Steel, in Phila Pa., and Olympia Buildings from Florida, but made in Pittsburgh Pa. I'm hoping to find some people who have gone through this process and can either recommend any company that's good to deal with, or warn me about any that might be a problem.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Thread starter DW1307

- Start date

Stephen Newell

Well-known Member

I'm in the woodworking business so because of cost I framed my building out of wood and covered it with galvalume. Other than cost I would rather have had an entirely steel building. I wouldn't have any reservations about purchasing a kit from any place. Before I built a building of my own I was in a leased metal building I liked very well. It had fiberglass skylights in it which really helped on lighting. The leased building was more climate controlled than the building I built though and the skylights in my building have a major problem with condensation. When the humidity is up it more or less rains inside the building. In hindsite it would have been better to put the fiberglass skylights at the top of the walls instead.

I don't know where you are. Here in the eastern US most people build what we call pole buildings. The upright members are set in very deep round hole footings with concrete and the building is braced across and topped with prefabbed roof trusses. I suggest you buy your favorite local contractor and architect a beer and ask them their advice before buying into a prefab manufacturer's product.

PoleBarnBuildings.com out of PA. Awesome experience and quality. These four guys show up. Two laying out and adjusting my lines and digging the post holes. One guy goes to the steel pile and one guy goes to the framing pile. Both start snipping and sawing and never looked at a blueprint. No one hardly talked. Serious workers. Gone the next day. 24x32 plus a 10ft car port on the side. 3 windows one entry door. 16x 12 insulated door on one end and a 12x12 on the other end. 21 grand to include the concrete.

you did not say how big but i put up 40x110x16 high side 14 low side steel frame and i did about 80% by myself very easy everything was numbered and everything fit like it should have was kind of fun and did not have enough left over to make a dog house this was a commercial building but for AG use is the same. hardest part is sorting everything out they know how to pack things when they brought it it was not a very big pile.was not one thing missing .the assembly plans were very good

DoubleO7

Well-known Member

- Location

- Crystal River, FL

Steel building as in steel carport steel.

Or red metal skeleton and steel siding?

Traditional Farmer

Well-known Member

- Location

- Virginia

Friend on neighboring farm put up a metal 60 X 30 shop about 30 years ago several of us helped and it has been a great building to work in we did a lot of projects and repairs there.Sadly his health has failed and he's not able to work there anymore,I can still use it anytime I want.

For a shop all metal is the only way I'd build don't want any wood in it.

For a shop all metal is the only way I'd build don't want any wood in it.

fastfarmall

Well-known Member

I would say good,if you build one like friend of mine, the top and bottom chord in the rafters are made out of 4x4x1/4 square steel tubing, there are 4 -40 foot sticks in the top chord, talk about strength it sure should hold any snow load we have in the north country,or tornado's, plus the rest is made up of angle iron,He built the rafters all last winter himself!

Goose

Well-known Member

Were you going to put it up yourself, or have the company put it up?

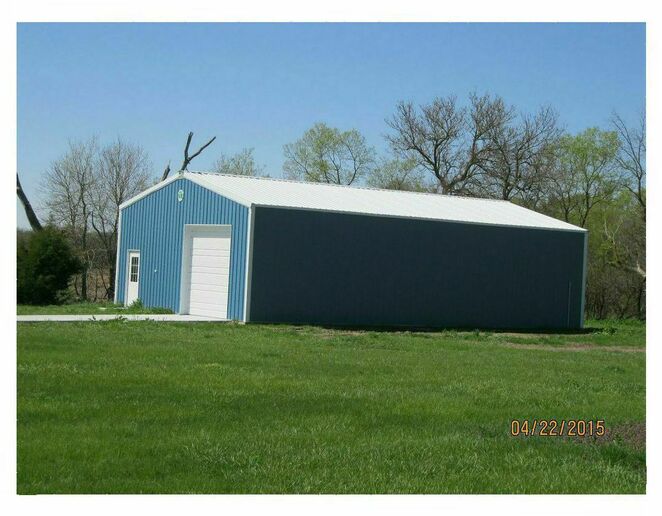

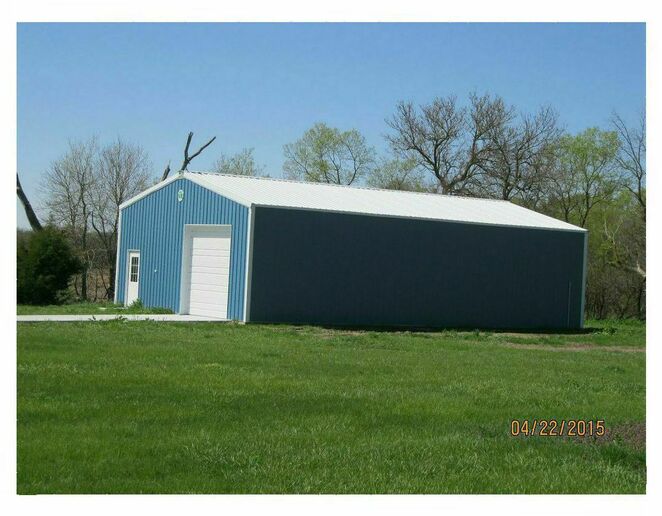

This is a 30x48 Cleary building I had put up in 2013. After I did the grade work, the Cleary crew put the building up in about 3 or 4 days.

The building itself was about $15,000 erected and the concrete floor another $6,800. I did the electrical wiring myself, and have around $23,000 in it.

This is a 30x48 Cleary building I had put up in 2013. After I did the grade work, the Cleary crew put the building up in about 3 or 4 days.

The building itself was about $15,000 erected and the concrete floor another $6,800. I did the electrical wiring myself, and have around $23,000 in it.

Logan in SE Texas

Member

IF, big word, you are going to hire someone to erect it for you, figure out who that will be!!! They will know which building suppliers have the best product for your area. Don't ask me how I know, it was an expensive lesson.

Naylorbros

Member

In the last five years we have put up three buildings. All were built by Nucor steel. Nucor builds an excellent high quality product and you will pay for it. When we were planning on replacing a wood pole hay barn that burnt down I said I do not want a wood frame or wood poles stuck in the ground to rot off. Two pictures. One if of the hay barn, a 50'x 75'. There is a 50 x 50 area for hay storage and a 25 x 50 enclosed storage area. The building was built high enough to easily get a 1069 New Holland Bale wagon in it. Later in the year we built the building we added a concrete floor to the hay storage area. The other picture is of the 60' x 75' equipment storage shed being built. A couple of changes I would make to this building now would be a two foot wider door. A 16' cut hay swather that is almost 18' wide overall is a bit of a tight fit for me through a 20' door. I would also make the door two foot higher. The door is 12' high and the bale wagon is 11'11" high.

Naylorbros

Member

the last picture

bjb in TX from Ne

Member

I worked the summer between undergrad and grad school at Behlen's in Columbus Ne.

1. You want someone regional, the major price differential will come from long distance shipping if you get too far out of your area.

2. Make sure your is engineered specifically for your location. A reputable manufacture will provide you with a sealed set of engineering drawings. A friend had one built here in Texas by a local contractor for a barndominum. Supposedly it was engineered, but I could tell from the pictures that it must have only been engineered once and they copied the same design all over the area...

3. Building longer will be cheaper than building it wider. You might even get a bigger building (sq footage wise) if you are flexible with the dimensions of the building.

4. If you are ok with tapered columns on the frames, it will be cheaper than having straight columns.

1. You want someone regional, the major price differential will come from long distance shipping if you get too far out of your area.

2. Make sure your is engineered specifically for your location. A reputable manufacture will provide you with a sealed set of engineering drawings. A friend had one built here in Texas by a local contractor for a barndominum. Supposedly it was engineered, but I could tell from the pictures that it must have only been engineered once and they copied the same design all over the area...

3. Building longer will be cheaper than building it wider. You might even get a bigger building (sq footage wise) if you are flexible with the dimensions of the building.

4. If you are ok with tapered columns on the frames, it will be cheaper than having straight columns.

bjb in TX from Ne

Member

The biggest thing will be are they using the correct wind load, snow load numbers for your specific area. The big deficiency in the metal building industry is if they say its design for 10 pounds per sq ft (psf) of snow load, and you get a wet snow that weighs 11 psf, you might need to go scrap the snow off the roof to prevent a collapse. They tend to engineer those buildings right to the edge...

If you email me a city or town near you I can look in my book to cross reference the MINIMUM design loads for your area.

If you email me a city or town near you I can look in my book to cross reference the MINIMUM design loads for your area.

Similar threads

- Replies

- 40

- Views

- 3K

- Replies

- 48

- Views

- 10K

- Replies

- 12

- Views

- 2K

We sell tractor parts! We have the parts you need to repair your tractor - the right parts. Our low prices and years of research make us your best choice when you need parts. Shop Online Today.

Copyright © 1997-2024 Yesterday's Tractor Co.

All Rights Reserved. Reproduction of any part of this website, including design and content, without written permission is strictly prohibited. Trade Marks and Trade Names contained and used in this Website are those of others, and are used in this Website in a descriptive sense to refer to the products of others. Use of this Web site constitutes acceptance of our User Agreement and Privacy Policy TRADEMARK DISCLAIMER: Tradenames and Trademarks referred to within Yesterday's Tractor Co. products and within the Yesterday's Tractor Co. websites are the property of their respective trademark holders. None of these trademark holders are affiliated with Yesterday's Tractor Co., our products, or our website nor are we sponsored by them. John Deere and its logos are the registered trademarks of the John Deere Corporation. Agco, Agco Allis, White, Massey Ferguson and their logos are the registered trademarks of AGCO Corporation. Case, Case-IH, Farmall, International Harvester, New Holland and their logos are registered trademarks of CNH Global N.V.

Yesterday's Tractors - Antique Tractor Headquarters

Website Accessibility Policy