steve terplak

Member

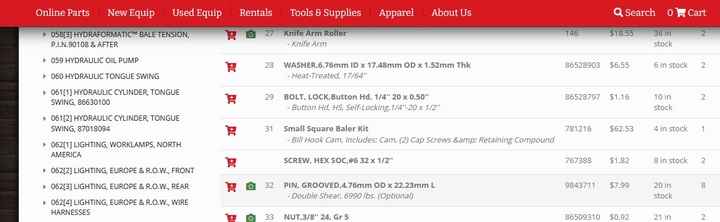

Baler question. Older New Holland. 311. Sheared the pin that holds the twine disc shaft onto the pinion gear. Knotter manual refers to it as a “grooved pin”.

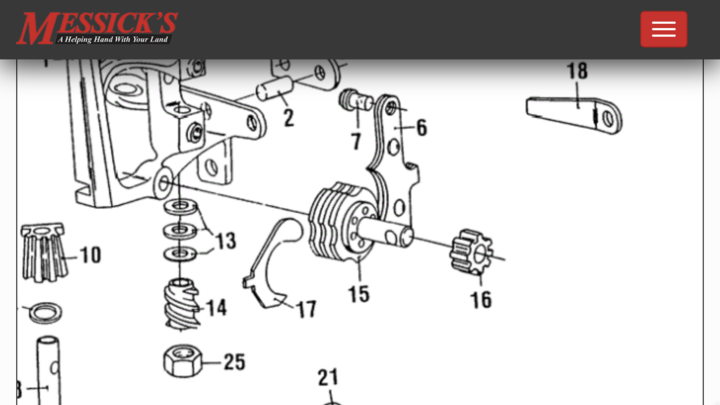

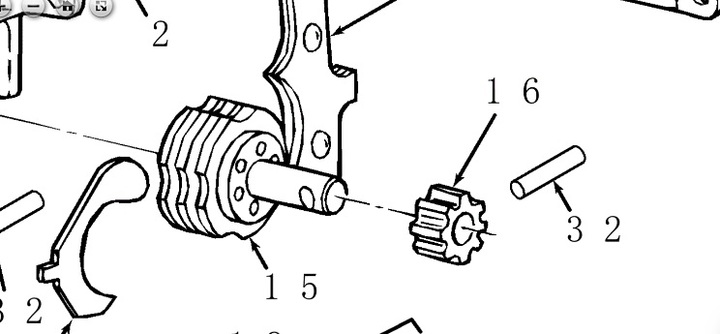

But parts diagram does not list it. It is #15 and 16 in diagram, no pin listed.

Why is it a “grooved pin”? From what I can tell hole in the gear and shaft are smooth.

Am I looking for a N.H. specific part here? Or can any solid pin work?

But parts diagram does not list it. It is #15 and 16 in diagram, no pin listed.

Why is it a “grooved pin”? From what I can tell hole in the gear and shaft are smooth.

Am I looking for a N.H. specific part here? Or can any solid pin work?