littlefarmer

Member

I'm looking to buy a John Deere 7000 planter for next year. I've been using a 494A (dad bought it in 1967, been using it every year since). However parts are getting hard to get. And there seems to be getting more problems with getting planting rates right, because it seems the seed corn companies are getting more and more careless with grading seed.

Some questions:

Are there still good 7000 planters around? How is it with parts for these planters?

When looking at one of these planters, what are the things a person should be looking at...common wear points, etc.?

I have 36 inch rows. Is it easy to change the row spacing on these planters?

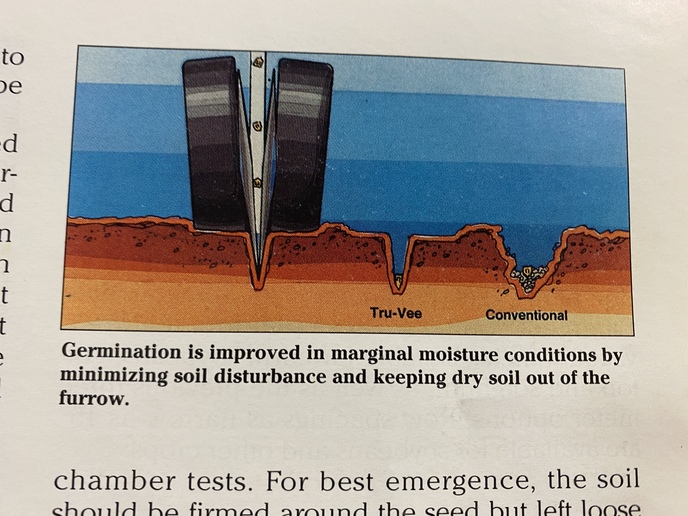

I do minimum till (but not no-till). How do these planters work for that?

Going to be using it for corn and soybeans. How do they do on planting beans?

Any other advice and/or recommendations appreciated. Thank you!

Some questions:

Are there still good 7000 planters around? How is it with parts for these planters?

When looking at one of these planters, what are the things a person should be looking at...common wear points, etc.?

I have 36 inch rows. Is it easy to change the row spacing on these planters?

I do minimum till (but not no-till). How do these planters work for that?

Going to be using it for corn and soybeans. How do they do on planting beans?

Any other advice and/or recommendations appreciated. Thank you!