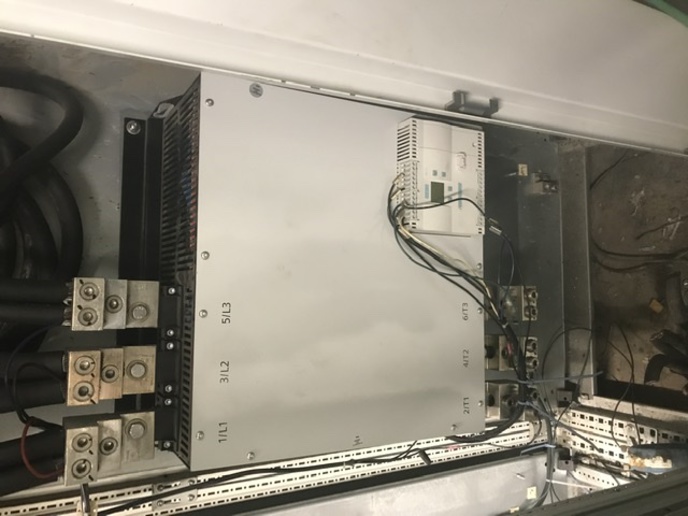

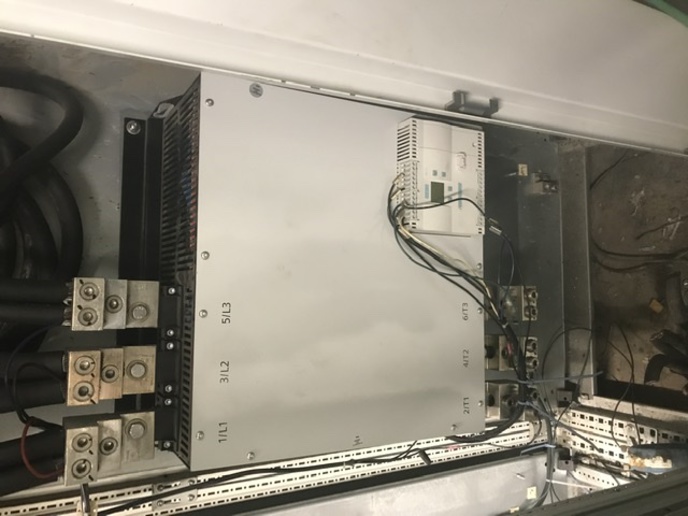

This is a 600hp motor that runs a backup ammonia compressor motor for Cavendish farms? freezers. The unit is scheduled for a compressor replacement so it?s also getting a new motor and new parallel runs of 500kcmil copper with ground straps to help deal with harmonics or electrical interference. Funny Phil25 mentioned going to a robot farm as we went to a former robot farm yesterday. They had 2 robots for 11 years but opted to trade them in in a parlour. To keep it tractor related they have a new John Deere hooked to the liquid manure spreader. Rough calculations at 14c/kWh ,if this motor was running 24/7 it would cost in the area of $45 000/mo to operate. The other picture is the soft starter so it powers up in stages ,600hp flicked fully on would be quite a wallope