grandpa Love

Well-known Member

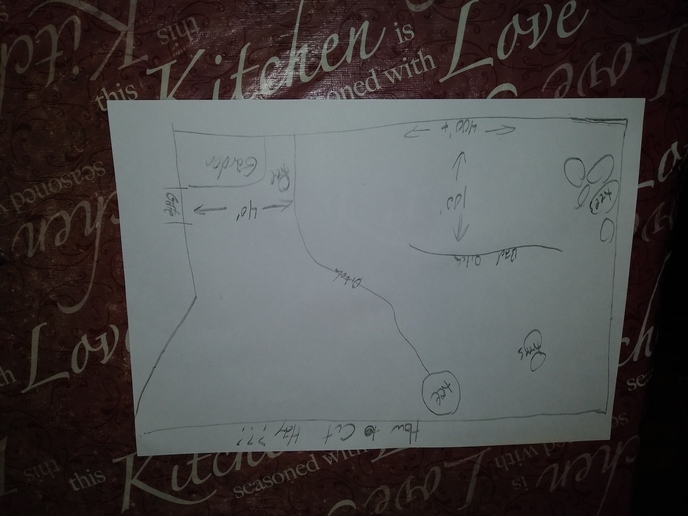

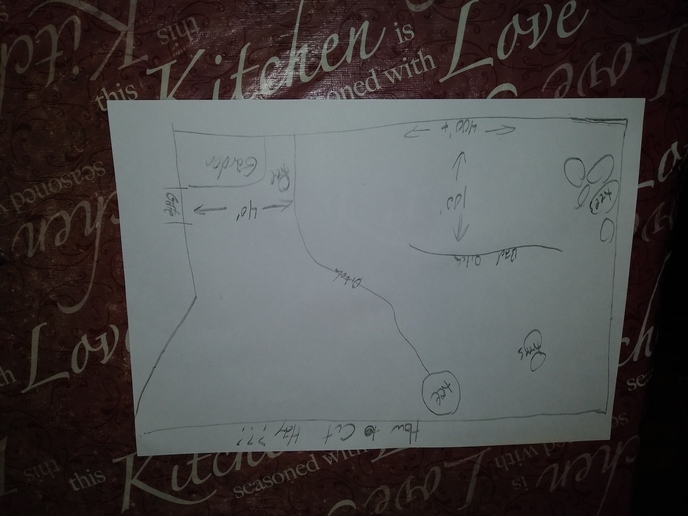

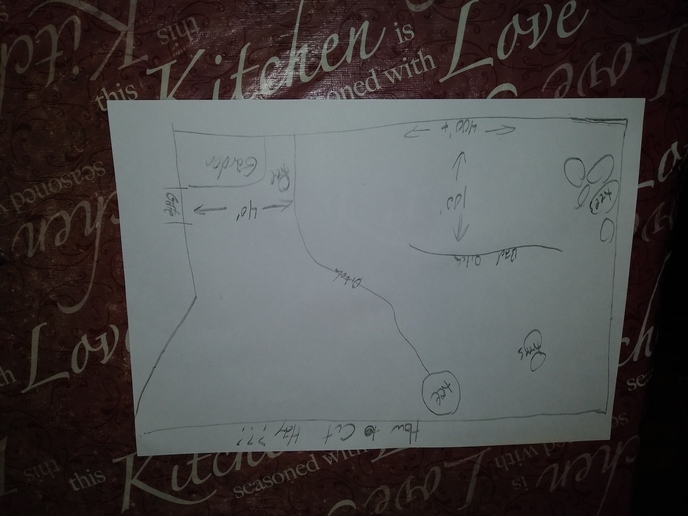

Showcrop asked in my post about my cutting pattern. I clearly need help! Any and all suggestions appreciated. I'm used to bush hogging, just get it cut.

(quoted from post at 09:00:41 04/16/20) My only advice is to start cutting clockwise until the field is cut, then do your trimming around the edges. If/when you screw up and get a fencepost into the mower, it will be on the trim pass and the field will already be cut. My neighbor always insisted on cutting the first pass counterclockwise. Then he always wasted precious time repairing the mower before he could get the rest of the field laid down.

(quoted from post at 09:38:34 04/16/20) The more you cut the field up the more corners and turning you'll have to deal with,no reason I can see for you not to go around the outside and just keep circling.I usually

cut 3 or 4 rounds and then cut the back round,then rake and bale the same way.

I do it exactly like Bruce described. Except I start with 8 rounds because it fits my rake better. I usually cut first round clockwise so I let the tractor find any fallen fence posts, branches or such rather than having the mower eat them.(quoted from post at 06:16:49 04/16/20) Just looking at my phone, I can?t make much sense out of your map, lol. I always cut 4-6 rounds, then pick the longest straight side in a odd shaped field as my guide. Then go make a cut up the Center of the field parallel to the longest straight side. Then turning to the left, cut back down the say swath I just came up. And turn left at the end and repeat widening out the Center strike until it looks like a shorter drive empty across the end that had the longest side, go down the longest side, and being turning right. This is cutting in strikes, and makes baling hay with a small square baler and a wagon behind much nicer job

(quoted from post at 09:36:55 04/16/20) Only seems like the younger ones like just cutting back and forth. I started mowing with a horse drawn mower pulled by a tractor. Only way that could be done was around and around. First piece of machineery I bought was a horse drawn mower in 1959. With those you would have to mow back and forth stop at each end raise cutter bar put out of gear turn and put bar back down and put in gear and how long would that take getting off unit twice for a pass with mower. And those mowers you had to raise bar slightlt to go over the cut hay to mow out the corners that the bar in front of wheels would not do. When the mower came out with wheels in back of bar eliminated that and semi-mount never had that strip left from turning. That is ifyou could make a square corner, turn wheel and hit brake and turn was made. Mow back cut first as that gives you correct starting point for going clockwise. Should be able tosee any obsticales laying in hay to go around them. If you try just going back and forth you have to wait to cut field untill those outside rounds are baled so you are not traveling on them all the time just trampling the hay into ground. And you will never make up lost time traveling empty across ends. The only time back and forth cutting makes any sence is with a self propelled outfit or a hydra-swing that you stay on same side for every cut and then you still have to wait for the outside rounds to get baled. If you have time for waiting from first cutting to baleing before cutting rest of field then might make sence but who has the time to do that. And either your bar mower or your mower-conditioner will make those perfectly square corners you do not have to cut out after rest of field is mowed. This works just as good on any shape field. Only split a field if it is large enough that you want tobale as seperate fields because you could not do it in one day.

(quoted from post at 08:03:35 04/16/20) Showcrop asked in my post about my cutting pattern. I clearly need help! Any and all suggestions appreciated. I'm used to bush hogging, just get it cut.

<img src="https://www.yesterdaystractors.com/cvphotos/cvphoto1684.jpg">

We sell tractor parts! We have the parts you need to repair your tractor - the right parts. Our low prices and years of research make us your best choice when you need parts. Shop Online Today.

Copyright © 1997-2024 Yesterday's Tractor Co.

All Rights Reserved. Reproduction of any part of this website, including design and content, without written permission is strictly prohibited. Trade Marks and Trade Names contained and used in this Website are those of others, and are used in this Website in a descriptive sense to refer to the products of others. Use of this Web site constitutes acceptance of our User Agreement and Privacy Policy TRADEMARK DISCLAIMER: Tradenames and Trademarks referred to within Yesterday's Tractor Co. products and within the Yesterday's Tractor Co. websites are the property of their respective trademark holders. None of these trademark holders are affiliated with Yesterday's Tractor Co., our products, or our website nor are we sponsored by them. John Deere and its logos are the registered trademarks of the John Deere Corporation. Agco, Agco Allis, White, Massey Ferguson and their logos are the registered trademarks of AGCO Corporation. Case, Case-IH, Farmall, International Harvester, New Holland and their logos are registered trademarks of CNH Global N.V.

Yesterday's Tractors - Antique Tractor Headquarters

Website Accessibility Policy