You can practice by putting that one back in,,and pulling it back out again. Did you measure how much spread you applied with the spreader? There is a max spec

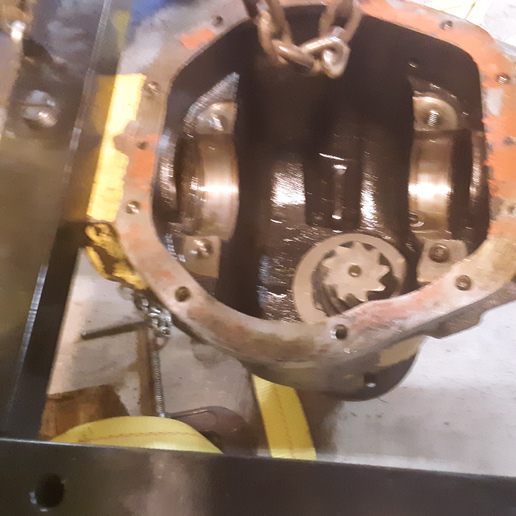

5. Install suitable case spreader and dial indicator on housing as shown, preloading indicator approximately 1/2 revolution. Ensure that mounting dowels are fully seated in housing and that clamps are securing spreader in proper position.

6. Zero dial indicator, then rotate spreader screw to spread housing 0.015 inch.Do not spread housing more than 0.020 inch, as housing will be permanently distorted.

7. Remove dial indicator, then the differential case and side bearing races from housing. Place bearing races with respective caps.

8. Remove spreader, then on front drive models, remove inner oil seal using suitable drift or axle shaft.

9. Measure pinion rotating torque (bearing preload) using suitable torque wrench. If preload is not within specifications, or if end play is present, pinion must be disassembled for inspection.

10. Hold companion flange with suitable tool and remove pinion nut and washer.

11. Remove companion flange with suitable puller, then pry pinion seal from housing.

12. Press drive pinion and rear bearing assembly from housing, taking care not to damage pinion.

13. Remove pinion preload shims from pinion and retain for assembly, then press bearing from pinion.

14. Remove front bearing, seal, gasket and slinger from housing, as equipped.

15. Drive pinion bearing races from housing using brass drift, place races with respective bearings, then remove pinion depth adjusting shims and retain for assembly.

16. Inspect components as outlined in "Cleaning and Inspection," keeping components in order, and replace as needed.Components that are to be reused must be installed in original position to ensure proper operation.

[/img]