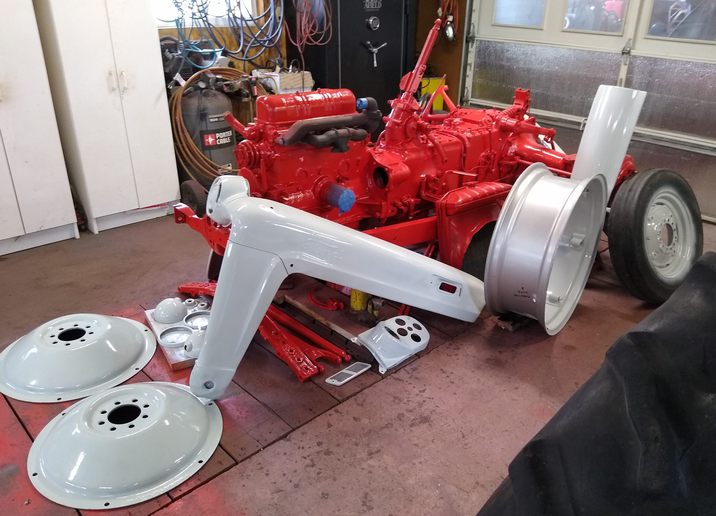

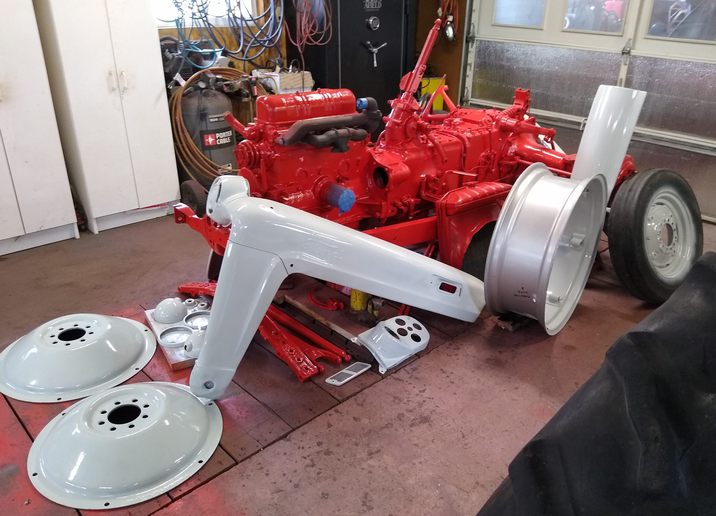

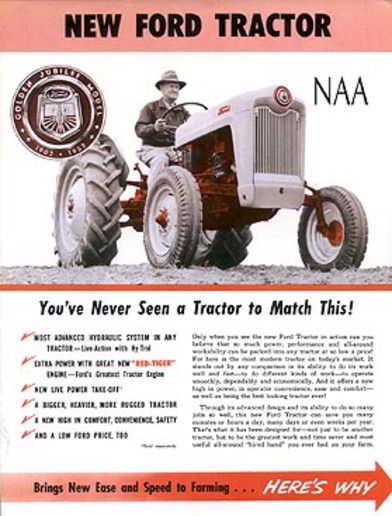

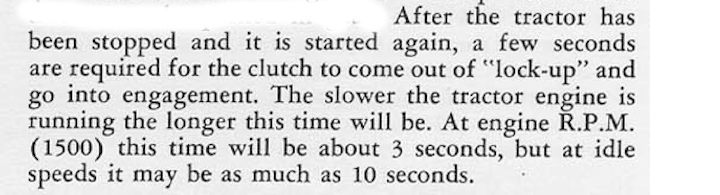

Last Fall, I went to a friend's auto junkyard. I was searching for a good 4L60E transmission core for my 1994 Chevy K2500. To my surprise that transmission was only made two years and is hard to find, but that is another story. I came across a 1995 trans that is even more rare and was only made one year. All that surprised me. While I was searching in the old part of the junkyard, I came across a Ford Jubilee tractor that was made the same year as me (1952). I did not need another tractor nor did I want another Ford. But . . my junkyard-empire friend told me it ran when parked there 5 years previous and would sell it cheap. So I cleaned out the carb, put new gas in it, stuck a 12 volt battery in it - and it started right up. I then drove it around and it ran surprisingly well even though the tires were flat. So I reluctantly bought it for $800 with a crappy front loader and still have not found my Chevy truck transmission. This is the story I got with the tractor. The junkyard owner wanted a tractor to run a brush-cutter. He bought this one from his uncle thinking it was ready to use. The engine never ran right so he hired a kid who worked at the local New Holland dealer to work on it. The kid just made it worse so the tractor was given up on and left in the junkyard (until I came across it). It seems that problem was caused by the wrong coil. This tractor had a new electrical system including a rebuilt 6 volt generator, new voltage regulator, and new ignition parts including a new coil. Problem was - the coil was made for 12 volts only and the tractor was being used with a 6 volt system. When I stuck the 12 volt battery in it, it ran fine. Once I got it home and put the proper 6 volt battery in, it was near impossible to start. Coil has 3.3 ohm primary windings and is meant for 12 volt systems only with no added resistor. I decided to convert to a 12 volt system anyway so that coil worked out fine. I also added a Pertronix breakerless Ignitor kit. No other mods needed. Coil was perfect for the Pertronix and so are the solid copper spark plug wires. Now - here is the weird thing. I parked the tractor in my barn once I had it running good. I had no intentions of doing any more work to it. A while later, I went to move it. I started it up, let the clutch out in 1st gear and NOTHING. No other gears worked either. I kept pushing the clutch in and out and slowly the tractor started trying to move. Finally it started to work normally. Seemed odd but I figured it had clutch problems?? All adjustments were fine. I parked it again. Later this winter, I pulled it into my shop. I split it and took the clutch out. It looked fine. I can see nothing wrong with it. Regardless, I got a new clutch kit here from YT and put it in. Once apart - I found other small things wrong. So, I ended up fixing every flaw I came across including a bad back wheel that was splitting in two. THEN - I decided to paint it which I hate doing. Got this thing all back together and guess what? It still will not move after I park it. Even for just half an hour. I just have to keep playing with the clutch jamming it in and out and eventually the tractor starts to move. It acts like it has a torque converter full of cold oil. Kind of perplexing. I noted that when I engage the PTO, and try to move the tractor - when it fails to move when in gear - the PTO turns fine. So now what?? I have never come across an issue like this in a pure gear-drive tractor. I am thinking maybe sheared rivets or bolts on the ring gear in the differential? At this point - nothing comes to mind other then just pulling the differential apart and looking for something wrong. Note - when it fails to move there are NO odd noises. Nothing that sounds like metal binding or slipping, stripped splines or gears. Pure silence. When it first starts to move a little, also no noise. I used to have a Case 580CK with a torque-converter drive and that is exactly how it always acted when cold (below 10 degrees F). I would play with the clutch pedal and eventually it would warm up and move. That is how this Ford NAA/Jubilee is acting except it is all gear drive. I would think that if the ring gear rivets or bolts were broken, it would not at first NOT move, and then get better after awhile and be silent. One other thing. Does anyone know what the original Jubilee badge looked like? The badge on this is all metal and supposedly is original. All chrome though with no color. Was it originally painted and got worn? I hand painted it with some gold and red and looks fine for what I want. I AM wondering though if the badge is OEM.