You should upgrade or use an alternative browser.

- Thread starter TDJD

- Start date

Do you have smooth - underserrated - top serrated sections?

I use an angle grinder to "touch up" the tops of my top serrated sections.

Ledger plates are ? of the system. Are yours worn down to smooth corners?

Roger in Iowa

Well-known Member

Sharpening of the sickle (knife) is best done with it out of the cutterbar. Angle grinder is fine. Yes, there is a special stone and grinder, but not cost effective unless you are going to be sharpening often, like twice a day.

If sections are worn to far, best to replace them too as the heat treat is only so far/deep!

BarnyardEngineering

Well-known Member

- Location

- Rochester, NY

If you have top serrated sickles you can't sharpen them at all. Not sure about bottom serrated but I'm thinking once the serrations are gone they won't hold an edge even if you do sharpen.

In this day and age sections are easy to find and relatively cheap, so replacing them is the best way to go.

larry@stinescorner

Well-known Member

old

Well-known Member

- Location

- Camdenton Missouri

Traditional Farmer

Well-known Member

- Location

- Virginia

Waste of time to sharpen the sections,get the riveted sections they're cheaper,will work with your hold downs.I rarely knock a section out anyway.only take you a few minutes to pull the blade and replace a section anyway.

c.oawright

Member

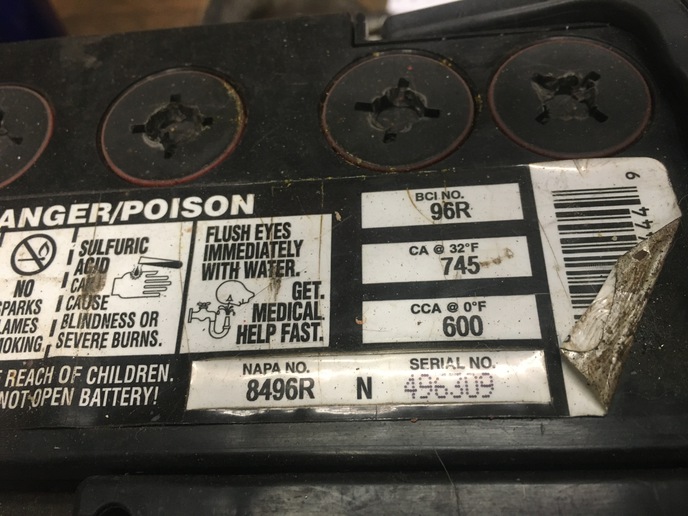

Knife sections.

J.Wondergem

Well-known Member

- Location

- Rockford, Mi.

If you decide to use rivets, get a get a rivet tool. I have one and it takes all the work out of it. Shoups has them. item number R3030

Moonlite37

Well-known Member

Moonlite37

Well-known Member

showcrop

Well-known Member

(quoted from post at 16:06:31 01/31/20) This man just asked a simple question about how to sharpen his sickle. Apparently he is not with a lot of hay to cut, or he would be using something other than a #5. He said he had bought a sickle with under serrated sections and he just wants it sharpened. he should take the deckle out and grind with his angle head grinder at the same angle as the original edge. Spend NO money! Just sharpen the sickle. More information: All guards wit replaceable ledger plates are serrated. If he asks the time, do not tell him how to build a watch.

Moonlight, are you holding court and issuing fines too? or just handing out written warnings?

glennster

Well-known Member

James Howell

Well-known Member

If you are not in a hurry, you might consider using a small, flat file to sharpen each knife section.

With bottom serrated sections, sharpen from the top towards the serrated edge.

You can remove the guard if necessary.

Hope this helps.

Similar threads

- Replies

- 17

- Views

- 520

- Replies

- 27

- Views

- 997

We sell tractor parts! We have the parts you need to repair your tractor - the right parts. Our low prices and years of research make us your best choice when you need parts. Shop Online Today.

Copyright © 1997-2024 Yesterday's Tractor Co.

All Rights Reserved. Reproduction of any part of this website, including design and content, without written permission is strictly prohibited. Trade Marks and Trade Names contained and used in this Website are those of others, and are used in this Website in a descriptive sense to refer to the products of others. Use of this Web site constitutes acceptance of our User Agreement and Privacy Policy TRADEMARK DISCLAIMER: Tradenames and Trademarks referred to within Yesterday's Tractor Co. products and within the Yesterday's Tractor Co. websites are the property of their respective trademark holders. None of these trademark holders are affiliated with Yesterday's Tractor Co., our products, or our website nor are we sponsored by them. John Deere and its logos are the registered trademarks of the John Deere Corporation. Agco, Agco Allis, White, Massey Ferguson and their logos are the registered trademarks of AGCO Corporation. Case, Case-IH, Farmall, International Harvester, New Holland and their logos are registered trademarks of CNH Global N.V.

Yesterday's Tractors - Antique Tractor Headquarters

Website Accessibility Policy