Dave H (MI)

Well-known Member

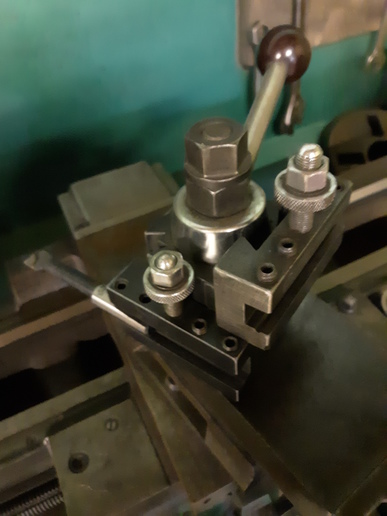

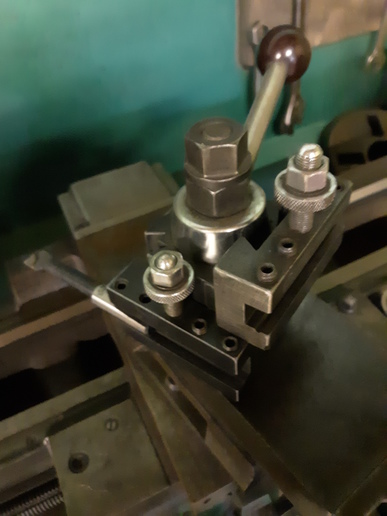

Things I mostly know what they are...two keyless chucks, two live centers with different configurations, a dead center with a pretty dull point and a spanner wrench of some sort. Thinking it has to do with the chuck. Also a picture of the tool post.

Not 100% sure of the use of the wrench. Not real sure what the two different designs on the live centers is for. The drill chucks are pretty much the same other than different widths on the knurled portions. The tool post looks like it holds two tools at once but not sure if there is reason other than convenience...any info appreciated. I've learned a lot posting these pictures.

Not 100% sure of the use of the wrench. Not real sure what the two different designs on the live centers is for. The drill chucks are pretty much the same other than different widths on the knurled portions. The tool post looks like it holds two tools at once but not sure if there is reason other than convenience...any info appreciated. I've learned a lot posting these pictures.