You should upgrade or use an alternative browser.

- Thread starter SVcummins

- Start date

Brendon-KS

Well-known Member

- Location

- Goessel, KS

farmerjohn

Well-known Member

Blackhole49

Well-known Member

- Location

- White Lake MI

MarkB_MI

Well-known Member

- Location

- Motown USA

Somebody stole your idea, George!

Case Nutty 1660

Well-known Member

cnt

BarnyardEngineering

Well-known Member

- Location

- Rochester, NY

(quoted from post at 04:00:41 10/29/19) Ropes for the clutch?how do you shift gears?

You get off, walk up, and shift into whatever gear you want. It's most likely an over center hand clutch so when the lever's pulled the clutch is disengaged.

Not much shifting going on.

Indiana Ken

Well-known Member

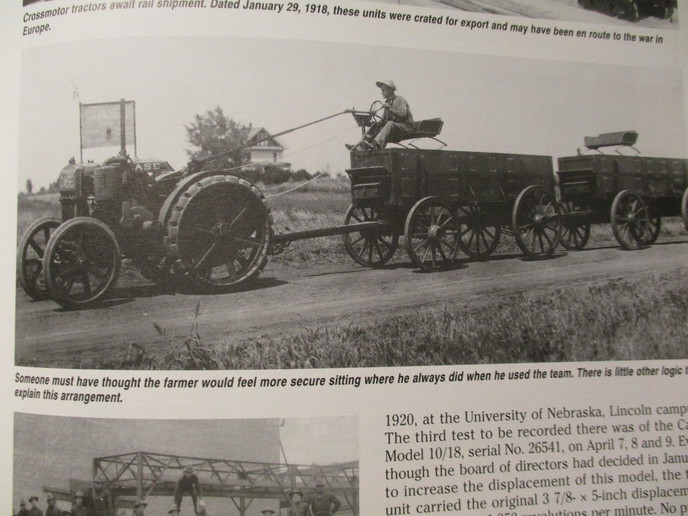

Think of it in terms of a team of horses. Horses could get spooked, stung by bees etc. Lots of ways to get hurt back then.

Steve@Advance

Well-known Member

I've heard the early automobiles came with warnings that the vehicle didn't respond to verbal commands, could not find it's way home on it's own, and had to be stopped and steered by the driver as it could not see objects in it's way.

That looks dangerous, but take in consideration, how much control over a horse does the driver ultimately have? At least the tractor is not afraid of snakes or barking dogs!

teddy52food

Well-known Member

Goose

Well-known Member

It worked good, except for the time one of the steering ropes broke and the whole thing went around in circles til he jumped off the binder and ran up and stopped the tractor.

By then, my sister and I were big enough to ride the binder.

37chief

Well-known Member

- Location

- California

cumminspuller

Member

Case Nutty 1660

Well-known Member

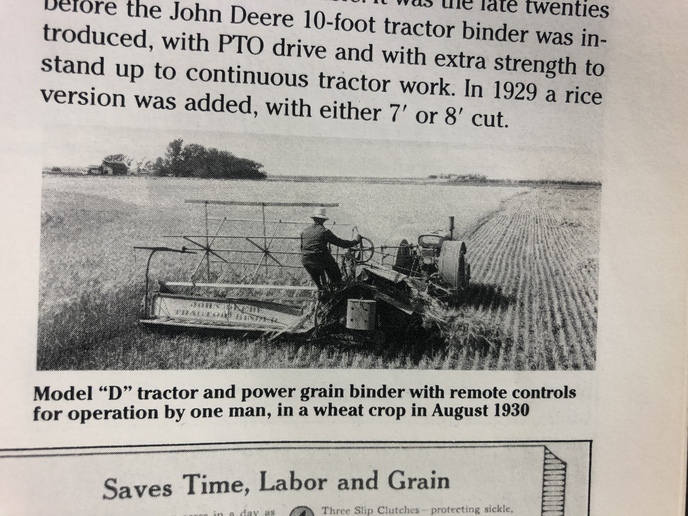

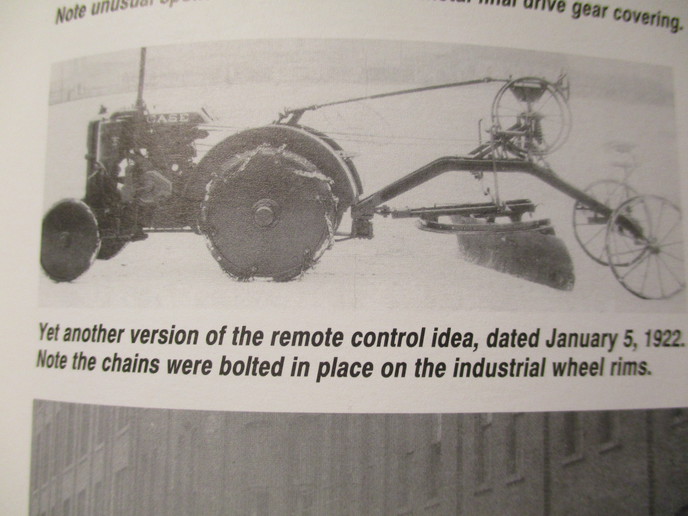

Bisset semi mounted binder

Bob in Australia

Member

Next innovation was hydraulic lift on pto header so tractor driver could lift header comb from the tractor. That was much safer. Next came many different self propelled headers (combines), and they have got larger and larger. Dad's header had 10 foot cut and ran at 2 miles an hour. We now use 42 foot cut running at 10 miles an hour.

Southern Ray

Well-known Member

Similar threads

We sell tractor parts! We have the parts you need to repair your tractor - the right parts. Our low prices and years of research make us your best choice when you need parts. Shop Online Today.

Copyright © 1997-2024 Yesterday's Tractor Co.

All Rights Reserved. Reproduction of any part of this website, including design and content, without written permission is strictly prohibited. Trade Marks and Trade Names contained and used in this Website are those of others, and are used in this Website in a descriptive sense to refer to the products of others. Use of this Web site constitutes acceptance of our User Agreement and Privacy Policy TRADEMARK DISCLAIMER: Tradenames and Trademarks referred to within Yesterday's Tractor Co. products and within the Yesterday's Tractor Co. websites are the property of their respective trademark holders. None of these trademark holders are affiliated with Yesterday's Tractor Co., our products, or our website nor are we sponsored by them. John Deere and its logos are the registered trademarks of the John Deere Corporation. Agco, Agco Allis, White, Massey Ferguson and their logos are the registered trademarks of AGCO Corporation. Case, Case-IH, Farmall, International Harvester, New Holland and their logos are registered trademarks of CNH Global N.V.

Yesterday's Tractors - Antique Tractor Headquarters

Website Accessibility Policy