Steve in IL

Member

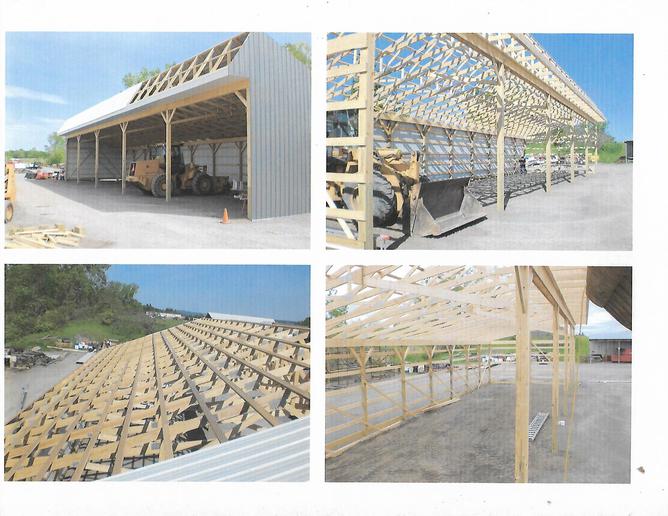

Looking at building a 40X64X14 basic pole barn for equipment storage. Had a 10 year old barn at the old farm, built by Blunier Builders. We really liked it. Built with columns made from 3 nailed 2X6s. Treated portion was buried in the ground. Seemed to work good. 3 laminated boards also seem to work well to hold trusses directly on top (center column board is slightly shorter, providing a notch), for 8' centers. I noticed that Blunier now promotes a stainless steel pier/bracket, but still uses the laminated columns.

Now, looking to build a new barn in central Ohio. Local builders here do not seem to be such big fans of the laminated columns. And they like trusses on 4' centers. One thing I really liked about the 8' centers was that no header board is required, which enables a 2' clear panel to let light in.

Any comments out there on the pros and cons of treated 6X6 poles and laminated 2X6 columns? Also any thoughts on buried poles/columns vs. piers options?

Thanks, Steve

Now, looking to build a new barn in central Ohio. Local builders here do not seem to be such big fans of the laminated columns. And they like trusses on 4' centers. One thing I really liked about the 8' centers was that no header board is required, which enables a 2' clear panel to let light in.

Any comments out there on the pros and cons of treated 6X6 poles and laminated 2X6 columns? Also any thoughts on buried poles/columns vs. piers options?

Thanks, Steve