RWB, great questions, let me try to clear up any confusion for you.

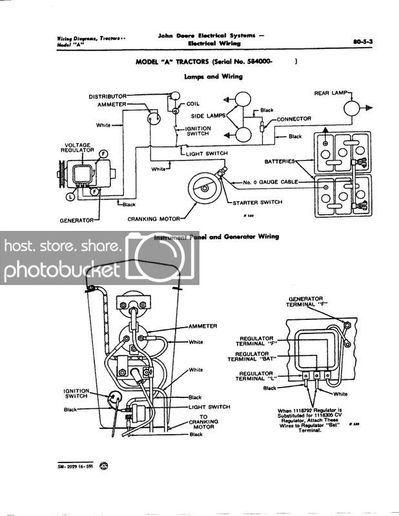

1) If your model A does (if its 12 volt but uses a 6 volt coil) NOT happen to have any ballast by pass while cranking feature, then its correct there's ONLY a single wire to the coils INPUT and a single wire from the coils other OUTPUT terminal to the distributor. And yes there's NO SWITCH by passing the resistor. Its "possible" on a 12 volt tractor to use a 6 volt coil plus a ballast and not use any ballast by pass when cranking feature. Its also possible to use a 6 volt coil with ballast on a 12 volt tractor and have the ballast by pass when cranking feature.

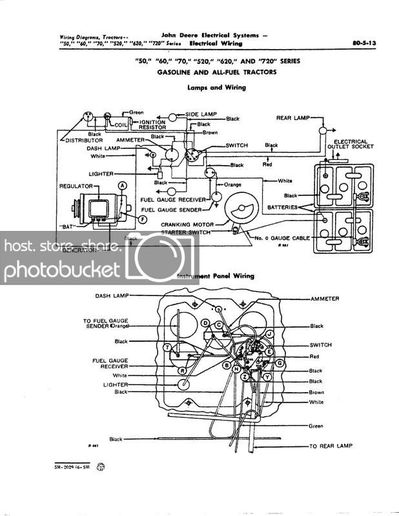

2) HOWEVER later model 12 volt John Deere tractors such as 50, 60, 70 etc that are 12 volt but use a 6 volt coil DO HAVE THE BALLAST BY PASS WHILE CRANKING feature and do have TWO wires to the coils INPUT. How the ballast by pass while cranking feature works on that series of tractors is there's an extra small side terminal on the saddle mount mechanical push switch on the starter that's hot ONLY WHEN CRANKING and it sends unballasted battery voltage up to the coil therefore directly by passing the ballast to improve cold weather starting.

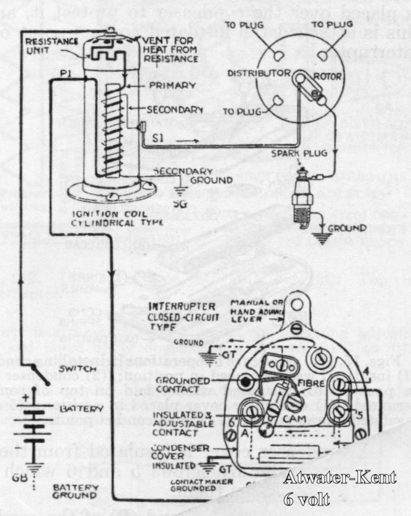

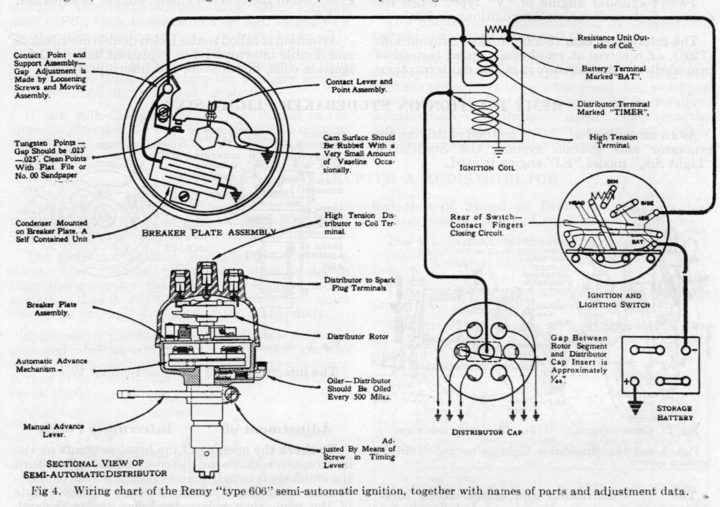

3) Many tractors and brand of tractors and other 12 volt vehicles used 6 volt coils with a ballast PLUS had the ballast by pass when starting feature. They worked in different ways including but not limited to

1) A by pass switch/terminal on the mechanical push starter switches to send unballasted voltage to the coil by passing the ballast but ONLY when cranking.

2) An extra I terminal on an electric starter solenoid that by passed the ballast

3) Temperature compensating (Thermistor??) wire from switch to coil that was low resistance when cold but resistance increased once up to temperature IE NO SWITCH OF ANY SORT WAS NECESSARY

4) Ballast resistance in the form of resistive wire link versus the traditional white bathtub ceramic looking units

5) Such ballast devices may be stand alone or mounted on the ignition switches or wire links from switch to coil

A purpose of 6 volt coils plus ballast on 12 volt tractors or cars was the ability to by pass the ballast when cranking to improve cold weather starting AND MANY MANY CARS TRUCKS N TRACTORS used one of the methods above.

As temperature decreases and its hard to crank a tractor and doing so draws extreme high amps the battery voltage drops. THEREFORE that's a good time to help increase coil voltage by by-passing the ballast when cranking. That's why you see 6 volt coils on 12 volt vehicles and the ballast by pass when cranking feature IT HELPS COLD WEATHER STARTING !!!!

Hope this helps, post back any questions, here are a couple pictures for you

John T