The guy Dad worked for when I was a kid had one, so yes, I'm 'experienced'. First: I hope you are merely idly curious and not seriously thinking of trying to make feed for livestock with one. A Roto-Baler is a fun gadget to fiddle with IF you are baling someone else's hay on someone else's land and there's someone standing by with a real baler to finish up after you get tired of playing with your toy.

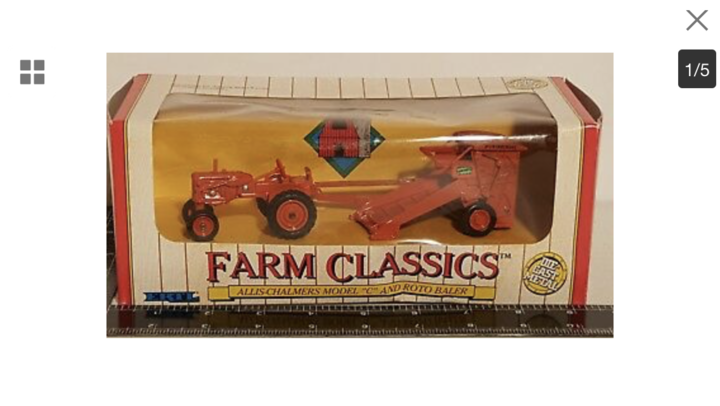

THE THEORY: It was about a half-step between loose hay and square bales. Cheap to buy (I assume, as all AC machinery was lightly built), cheap to run (used binder twine instead of the heavier baler twine), and you really needed an AC tractor with hand clutch and live pto to run one properly. Any regular tractor would destroy your clutch leg (and the clutch disk). Later models were designed so you didn't have to stop- the hay was sort of recirculated while the wrapping was in process, but that was very late and farmers had had enough of the whole concept by then.

You had to rake two windrows side-by-side or else try to weave on a single windrow to make tight, straight bales. Weaving was almost impossible with such an ungainly hookup. In decent hay you couldn't get side-to-side fast enough to get an even feed before a (cone-shaped) bale was made.

I guess the bales might shed water to a degree, but you have to make many, many more of them so I suspect the actual spoilage in tons was about the same. Perhaps greater as it was impractical to put the bales in a barn, so they were stacked outdoors, if at all.

You can see in the video someone else linked how the thing 'operates' when it isn't trying to eat its own belts or wrap twine or hay around the rollers (congratulations to the editor!). Another poster also correctly mentioned the hay in that clip is not raked properly. Getting the proper twin windrows meant raking one windrow against the direction the crop was mowed, which usually doesn't work very well, unless you had a mower and a rake that each cost more than the baler (but you're a roto-baler owner, so of course you had neither).

THE REALITY: This machine taught more boys (and probably not a few girls) more words than any other machine in the history of agriculture. I vividly recall coming over a hill and, just before tractor and baler came into view, seeing a ball of binder twine arcing up into the air. In the linked video, you see the pickup stop and the twine arm drop. The last of the hay was supposed to carry the end of the twine into the chamber to wrap the bale. You also see the operator tossing some hay in to 'help' the twine when this didn't happen- which was pretty often. We don't see that bale, but it would have twine on maybe half of it. Not real safe, having to quickly hop off the seat with the pto running.

Once your 'baling' was done, there was the small matter of getting it off the field and into some kind of storage. As others stated, some guys would leave bales for the cows to pick over, but I grew up in an area where we made more than one cutting per season and we also wanted to cut hay the next year in the same field. A small heap of rotten hay was no fun to mow through, so we picked up the bales- even if they got rained on.

The bales are comparatively light, which was a small advantage when our baling 'crew' consisted of Dad, scrawny 9-year-old me, and my 10-year-old brother. Dad worked for an old cheapskate- when Dad would mention maybe updating some equipment, he would retell his story of selling apples on a street corner during the depression. But I digress. The total tonnage of hay is the same, no matter what kind of bales you make, so actually more work because more bales. Over time, we developed a system that made it doable:

The key was doing the least lifting possible. Dad built a sled out of a couple tree trunks about 24 feet long. Some sort of backstop on the rear but I don't recall details. Driver drove the sled as close to the bales as possible. With a longer hook than used with square bales, you could stab the end of a bale and drag it onto the sled. Sometimes a step or two off, but a dirty look at the driver got you closer to the next bale. Stack 4-5 bales high. When the sled was full, you went to the stack, which was long rather than high. Way too much work trying to make a tall stack of such loose, irregular bales. Stack the bales about 4-high- whatever you could reach from the ground- then a layer of plastic sheet and another row on top. A grown man doesn't really need a hook to handle the bales- the centers are soft, so you just grab the 'harder' out layer and it's easy to do what you want. It was a bit less work as you were mostly moving the bales sideways, not throwing them up.

Best thing that happened was my brother and I got big enough to handle square bales- square bales from the horrible old IH baler we had. I don't remember what model it was, but it had a huge flywheel and twine boxes on either side of the bale case which was a handy place for a kid to ride and tie the (many) knots the baler missed. But that's another story...