grandpa Love

Well-known Member

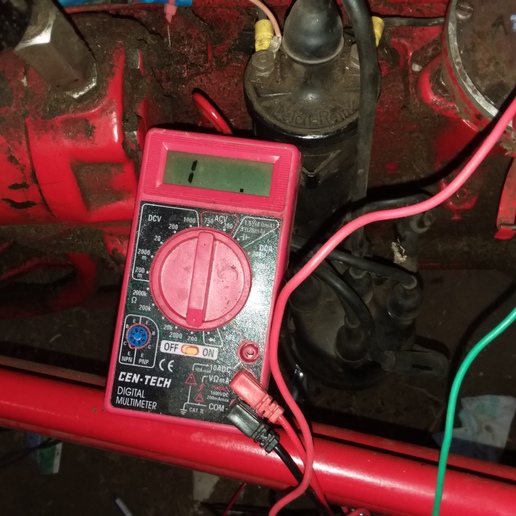

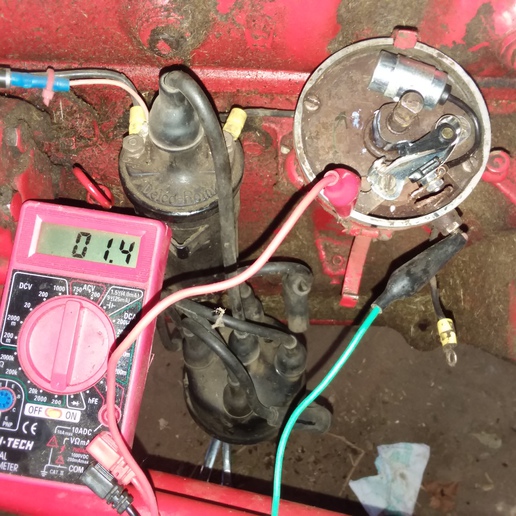

Key switch was having issues,you could jiggle it while pressing the start button and it would crank up. Well that stopped working so I got a wire with clips on it and put on on the each side of switch. No go. Left one on solenoid side and moved other one to the out side of ceramic resistor. Fired right up. Drove it around for 2-3 minutes and it back fired a couple times ,ran real rough for 15-20 seconds then died like switch was turned off. Will not be start. Power to coil...... haven't dug deeper. What's chance I fried something by passing that resistor? 49 front mount distributor,12 volt.fuel flow is good out carb plug. The front distributor is new to me. Will tackle it tomorrow afternoon......then on to the new 8n on the trailer.......