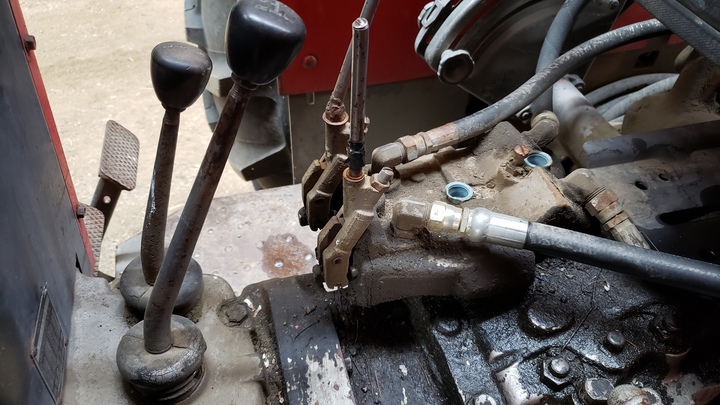

Just bought a MF 255. When trying it out the hydraulics on the front end loader worked well. I asked if the 3 point hitch worked - the owner said he hadn't used it for 10+ years but it had been working in the past. It didn't work when we tried it but after disconnecting the bucket tilt hydraulics and playing with the controls we got some movement. Got the tractor home but now when I use the tilt on the bucket the 3 point hitch moves along with it - either up or down. This causes some hesitation with the bucket which I don't like or want. The 3 point hitch doesn't move when using its designated controls. Would be nice (but not critical)to have the 3 point hitch working at this time but my preference is to have the bucket working properly.

Any ideas on how I fix this?

Any ideas on how I fix this?