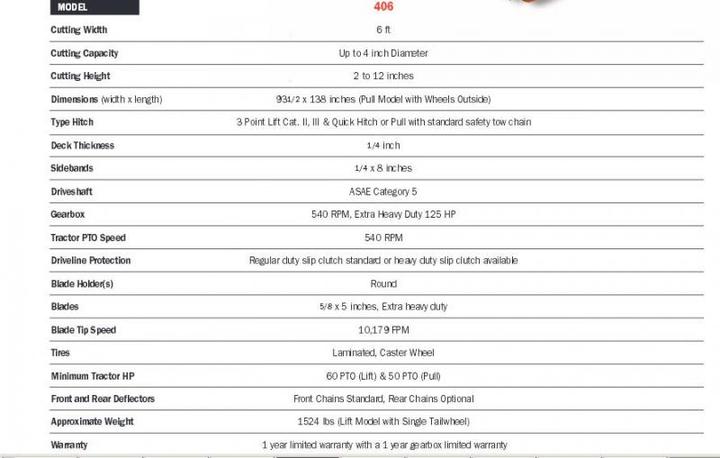

Ok I am in desperate need of a 6ft bush hog. Yes, here we call all rotary cutters a bush hog no matter the brand. Close by (1 hour drive) I can purchase either bush hog for relatively the same price $1,500. I normally cut the 10 acres at the house twice a year which consist of weeds a couple of feet high. Once a year I cut another property I own once a year which includes some saplings and taller weeds with lots of mature trees. I turn the cutter with a Kubota MX5200 hydrostatic with the front end loader removed. Which one of these is most desirable for my use?

Tennessee River Implements

I think I like the open back to discharge the cuttings and the 90 HP gearbox. I also like the beefy 3 point connection as I have twice backed my Howse cutter up near a tree and it has caught on roots and bent the poo out of the three point attachment.

Taylor Way

Looks like it is nicer and made with a higher standard in mind. Heavier metal, but only a 60HP gearbox. Round back which I do not know if this is a plus or not. The three point connection looks like it could be tweaked with a little abuse.

Tennessee River Implements

I think I like the open back to discharge the cuttings and the 90 HP gearbox. I also like the beefy 3 point connection as I have twice backed my Howse cutter up near a tree and it has caught on roots and bent the poo out of the three point attachment.

Taylor Way

Looks like it is nicer and made with a higher standard in mind. Heavier metal, but only a 60HP gearbox. Round back which I do not know if this is a plus or not. The three point connection looks like it could be tweaked with a little abuse.