Hi Folks,

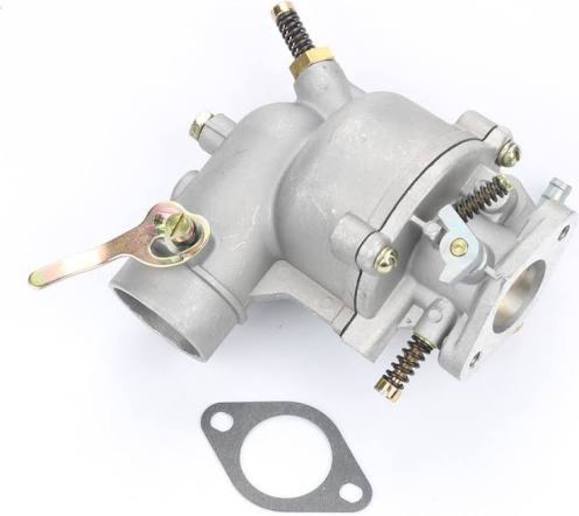

I'm restoring an old Bachtold mower ("The Whipper") with 8hp Briggs and Stratton engine (cast updraft carb). I'm a novice at small engine repair and have two questions:

1) I've tinkered extensively with crab adjustment screws (watched lots of YouTube videos) and can get the mower running well enough to operate. However, I can never get a low idle. What's my next step? Tear down and clean carb? Are adjustments to throttle necessary?

2) Maybe because of the idle issue, the drive shaft is ALWAYS spinning when the engine is running. As a result, when the clutch is disengaged, the shaft is spinning against the mower belt and burned it in two. Is this a belt tension issue, or an idle speed issue?

Thanks!

I'm restoring an old Bachtold mower ("The Whipper") with 8hp Briggs and Stratton engine (cast updraft carb). I'm a novice at small engine repair and have two questions:

1) I've tinkered extensively with crab adjustment screws (watched lots of YouTube videos) and can get the mower running well enough to operate. However, I can never get a low idle. What's my next step? Tear down and clean carb? Are adjustments to throttle necessary?

2) Maybe because of the idle issue, the drive shaft is ALWAYS spinning when the engine is running. As a result, when the clutch is disengaged, the shaft is spinning against the mower belt and burned it in two. Is this a belt tension issue, or an idle speed issue?

Thanks!