As anyone that tune's point ignitions know's (beit mower car or tractor)condensers don't last and often bad right out of the box. I know condensers and electronics are not the same thing but capacitors in electronics don't fail at the same rate. Conventional wisdom would say modern electronics technogly should make condenser manufacturing childs play compared to 50 years ago. Why are new condensers such a crap shoot? Other than specialized instrument or analog ohm meter,are other ways to test?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Thread starter da.bees

- Start date

TGP

Member

Agree with Bob because all they do is stick a little tiny modern capacitor that costs about half a cent into an old-style tin can with a wire lead coming out of it. Something like .22uF @50V is a real standard and cheap value. The old ones actually took up the whole can and were made of paper and tin foil rolled up together into a coil and waxed.

Tom

Tom

Russ from MN

Well-known Member

- Location

- Bemidji MN

My understanding is they don't wear out, they don't get weak. So if you have an old one that works use it forever! The idea of changing it every time you change points (a wearing part) is BS.

Deutz Lover

Member

The older electrolytic condensers were manufactured with wax impregnated paper and aluminum foil. These also had an internal spring to insure wire contact between the foil sheets and the wires. Eventuallly parts corrode or the wax deteriorates and the insulation breaks down or wire/foil contact fails.

Computer manufacturers had a rash of electrolytic capacitor failures around 2005-210. This type uses a liquid composition to wet the insulator between the foil plates. The cheap versions from some pacific rim countries had used an incomplete electrolyte formula (no hydrogen scavenger). These crap caps failed prematurely causing mother boards from a number of major manufacturers to quit. The caps would burst, swell, vent, or barf out a brown ichor. They have been replaced with solid electrolyte polymer capacitors with 10 times the service life of even the older correctly manufactured electrolytic caps.

Perhaps something similar has happened with the current condensers manufactured for older Kettering systems. The problem is that the market for decent ignition condensers has declined so low that no one has a reliable replacement type other than a very few companies.

Computer manufacturers had a rash of electrolytic capacitor failures around 2005-210. This type uses a liquid composition to wet the insulator between the foil plates. The cheap versions from some pacific rim countries had used an incomplete electrolyte formula (no hydrogen scavenger). These crap caps failed prematurely causing mother boards from a number of major manufacturers to quit. The caps would burst, swell, vent, or barf out a brown ichor. They have been replaced with solid electrolyte polymer capacitors with 10 times the service life of even the older correctly manufactured electrolytic caps.

Perhaps something similar has happened with the current condensers manufactured for older Kettering systems. The problem is that the market for decent ignition condensers has declined so low that no one has a reliable replacement type other than a very few companies.

(quoted from post at 22:48:10 02/15/18) My understanding is they don't wear out, they don't get weak. So if you have an old one that works use it forever! The idea of changing it every time you change points (a wearing part) is BS.

No they don't wear out but they can and will go bad.

Guys what has happened and will only get worse is demand. As old guys restore a tractor, then do everything in their power to make the ignition system last forever demand drops dramatically. So company A stops making points for that application because it isn't profitable. You can argue that people still buy those points but the bean counters know how much it cost for materials, labor, packaging, storage and distribution to a fraction of a cent. So here comes company X that's going to cut corners and use substandard materials. And there isn't much you can do. You either buy the garbage they produce or let it die and crush it.

Rick

I too had concluded that condensers don't hold up like they used to back in the 50s & 60s. In early years I don't recall ever having any condenser failures.

Then I got to thinking about it. Back in the 50s & 60s it was common practice to replace condensers routinely with an annual or mileage interval tune-up.

In more resent years the failures I have had are with condensers that are maybe 10-20 years old on equipment that is not used everyday.

Perhaps if if I would routinely replace all the condensers in all the tractors in the shed every year, I wouldn't have condenser failures.

Then I got to thinking about it. Back in the 50s & 60s it was common practice to replace condensers routinely with an annual or mileage interval tune-up.

In more resent years the failures I have had are with condensers that are maybe 10-20 years old on equipment that is not used everyday.

Perhaps if if I would routinely replace all the condensers in all the tractors in the shed every year, I wouldn't have condenser failures.

There have been many new capacitor failures in high-end TVs and computer monitors. Blamed a huge and bad run of Chinese caps.

I have never had a new one go bad yet in an ignition system.

Please explain "bad." Is your cap shorted, won't hold a charge, or measures wrong on the MFD scale.

I don't understand the comments about the old caps never failing. I check any I use with a cap-tested. The vast majority of the time - a wax-wound cap from the 40s-50s is nearly always BAD. Not shorted. Just dead and unable to hold a charge.

I also fix and collect old radios and in them too- the old caps have a high fail rate.

I have never had a new one go bad yet in an ignition system.

Please explain "bad." Is your cap shorted, won't hold a charge, or measures wrong on the MFD scale.

I don't understand the comments about the old caps never failing. I check any I use with a cap-tested. The vast majority of the time - a wax-wound cap from the 40s-50s is nearly always BAD. Not shorted. Just dead and unable to hold a charge.

I also fix and collect old radios and in them too- the old caps have a high fail rate.

I actually have a surplus US military condensor tester. It's taken me a while to learn how to use it, even though I have the manual, but every now and again I take a mess of questionable condensors and test them. Sometimes they are bad, others test good. But, I'm finding a higher percentage of bad than good these days.

Texasmark1

Well-known Member

Back in the 1965 time line when I was moonlighting in a TV shop, the only capacitor failures in TVs were the electrolytic power supply filter

caps. of 50-250 microFarad size. You could tell the bad ones as they would get a bulge where the terminals were attached to the plates.

Easy to detect. Either horizontal tearing was present or 2 powersupply "hum" bars would roll through the picture. Taking a jumper

capacitor and walking through the filters, when you got across the bad one, a snap and the picture was fixed. Removal and inspection

showed the rubber bulging from inside.

The paper-plastic, mica, and ceramic in fractional uF sizes seldom if ever failed.

caps. of 50-250 microFarad size. You could tell the bad ones as they would get a bulge where the terminals were attached to the plates.

Easy to detect. Either horizontal tearing was present or 2 powersupply "hum" bars would roll through the picture. Taking a jumper

capacitor and walking through the filters, when you got across the bad one, a snap and the picture was fixed. Removal and inspection

showed the rubber bulging from inside.

The paper-plastic, mica, and ceramic in fractional uF sizes seldom if ever failed.

I cant answer your question as to WHY, but as a past used tractor dealer and farmer and electronics hobbyist, its been my experience some (NOT ALL) NEW condensors are bad out of the box and so often (not always) an older original condenser is still fine and doesn't need replaced just as a matter of course, in some cases its better then the new one lol

WHY ?????? Qualty control,,,,,,,,materials,,,,,,,,,,environment in which they are used ??????????

John T Long retired Electrical Engineer

WHY ?????? Qualty control,,,,,,,,materials,,,,,,,,,,environment in which they are used ??????????

John T Long retired Electrical Engineer

dr sportster

Well-known Member

All I can add is if you have a Fairbanks-Morse mag you better use Fairbanks brand name points and condenser as aftermarket for that is junk.

All this talk and I still have not heard what a "bad" condensor is alleged to be?

A condensor/capacitor is rated at a certain MFD, isolation from ground - and a charge-holding capacity.

For those talking about "bad" caps - please explain the actual issue?

For myself - with ignition capacitors - I think I have seen maybe two in the past 50 years that were shorted. Old caps are often just dead with no ability to store a charge.

Most of the caps I replace are simply of the the specified MFD test range and would shorten the life of the points if used.

A condensor/capacitor is rated at a certain MFD, isolation from ground - and a charge-holding capacity.

For those talking about "bad" caps - please explain the actual issue?

For myself - with ignition capacitors - I think I have seen maybe two in the past 50 years that were shorted. Old caps are often just dead with no ability to store a charge.

Most of the caps I replace are simply of the the specified MFD test range and would shorten the life of the points if used.

Janicholson

Well-known Member

Condensers fail in three ways. Mechanical damage from condensation/corrosion/smashing, Internal short (could be clipping tops of of pulses with an internal spark through dielectric) or dead short, open from broken lead, or broken internal connection to "plates". I have seen them all and even new ones can be bad. I usually do not replace them unless the points are showing pits and peaks, or they test bad. Jim

john *.?-!.* cub owner

Well-known Member

I am an electronics technician as a profession (now retired), and old machinery is my hobby. Condensers and capacitors are electrically the same, but their use and physical construction is different. Condensers have to withstand much higher voltage spikes for their normal working voltage than capacitors normally do. It appears to me that the reasons for the modern condensers failure rate is that the companies selling them are buying them from the cheapest source they can find regardless of quality.

john *.?-!.* cub owner

Well-known Member

I strongly suspect that the manufacturers are simply putting a capacitor inside a tin can without taking into consideration the heat, physical vibration. and possibly even the voltage spikes.

Ted in NE-OH

Well-known Member

Old technology, points and condensers have gone away in modern equipment. No one wants to invest into a declining market. That is also true for 6 volt batteries.

BushogPapa

Well-known Member

Ditto...I test the old one and leave it in if it tests "Good"...

If need be, NAPA's "Best".."Standard" brand..

"Condensor" and "capacitor" mean exactly the same thing. One term is just older then the other. Mr. Volta is given credit for first using

term in the context of electricity in 1782. James Watt was using the "condensor" term for steam-pressure storage. It is assumed that since

fluid pressure and flow is often used as an analogy to describe electricity. So at the time, Volta calling his electrical "pressure" storage

device made sense. I have lots of radio repair manuals up into the 1950s that call devices "condensors" instead of "capacitors."

term in the context of electricity in 1782. James Watt was using the "condensor" term for steam-pressure storage. It is assumed that since

fluid pressure and flow is often used as an analogy to describe electricity. So at the time, Volta calling his electrical "pressure" storage

device made sense. I have lots of radio repair manuals up into the 1950s that call devices "condensors" instead of "capacitors."

9% won't have a clue unless they are a career failure analysis expert. From following several forums for years, I think? I can say with some confidence that most condensers that are declared bad are done so because a man replaced one & now his engine runs. Was it bad or did he inadvertently clean up a connection? Disturb a 'short'? an open? Who knows. And sure, I too "I want to hear specifically what he is calling "bad."(quoted from post at 14:27:15 02/16/18) I am well aware of how a capacitor can fail and how to properly test one. My question remains unanswered. The original poster says he has had "bad" ones and I want to hear specifically what he is calling "bad." Pretty simple question, I thought.

Zeke Boniface

Member

I have probably told these stories before, but that has never stopped me from telling one again.

From the time I was a teenager,(early 70's) I never threw a condenser away after a tune up. A few years ago, I retrieved them from the collection and tested them on a modern $400.00 (used) analyzer. Of a couple dozen, only two were of low capacitance, no shorts.

A friend (again, 70's) used to ask me to "tutor" him in automotive mechanics. Translated, "Can you do a tune up on my car while I watch?" This happened several times. I purchased the parts at the same place the local shops bought them. Some time after the last time he told me, "I had to be towed off the New York State Thruway! They said it was that condenser you put in!"

Zeke B.

From the time I was a teenager,(early 70's) I never threw a condenser away after a tune up. A few years ago, I retrieved them from the collection and tested them on a modern $400.00 (used) analyzer. Of a couple dozen, only two were of low capacitance, no shorts.

A friend (again, 70's) used to ask me to "tutor" him in automotive mechanics. Translated, "Can you do a tune up on my car while I watch?" This happened several times. I purchased the parts at the same place the local shops bought them. Some time after the last time he told me, "I had to be towed off the New York State Thruway! They said it was that condenser you put in!"

Zeke B.

I said"condensers don't last and often bad right out of the box.".(quoted from post at 13:27:15 02/16/18) I am well aware of how a capacitor can fail and how to properly test one. My question remains unanswered. The original poster says he has had "bad" ones and I want to hear specifically what he is calling "bad." Pretty simple question, I thought.

Specifically,what I'm calling "bad"is. After installing new points and condenser,the engine run's poorly within less than an hour of run time and changing condenser again cure's the problem. Specifically,what I mean by "condensers don't last long"is. Engine run's well after tune up for 6-24 months/10-50 hours then begain's random skipping or faltering that stops when condenser is replaced. Wherther that fit's your definition of bad and not lasting long,it's my definition. As I clearly indicated in the last sentence of original post,I have no way nor the skill of diagnosing which or what cause's condensers to act like that. Pretty simple answer I think. I'm sorry if lack of technical reasons bumfuzzel you.

If you did indeed have a bad capacitor - and it directly caused bad running, then it had to be partially shorted. If it was bad as in wrong or no capacitance - it would result in a weaker spark or the points pitting badly.

There was a HUGE problem a few years back with capacitors- but not the film-foil type used in points ignition systems. I had to fix quite a few failed devices with the faulty Asian electrolytic caps that burst.

There was a HUGE problem a few years back with capacitors- but not the film-foil type used in points ignition systems. I had to fix quite a few failed devices with the faulty Asian electrolytic caps that burst.

Deutz Lover

Member

JDEM,

I was wrong about the date, but I still saw a high number of boards and power supplies that had this problem after 2005. On the motherboards main ones that went were the ones that supplied power to the cpu and were high mfd. ones.

Crap Caps QED.

I was wrong about the date, but I still saw a high number of boards and power supplies that had this problem after 2005. On the motherboards main ones that went were the ones that supplied power to the cpu and were high mfd. ones.

Crap Caps QED.

Zeke Boniface

Member

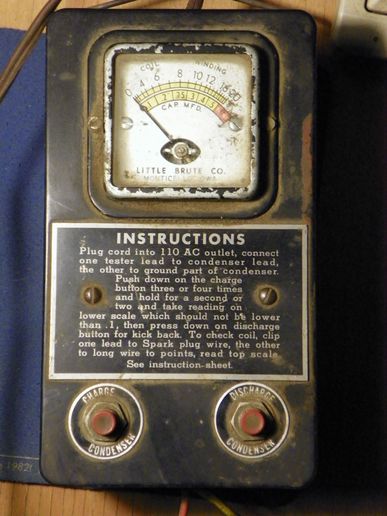

And then there's this...

Zeke B.

<image src="http://forums.yesterdaystractors.com/photos/mvphoto10834.jpg"/>

Zeke B.

<image src="http://forums.yesterdaystractors.com/photos/mvphoto10834.jpg"/>

We sell tractor parts! We have the parts you need to repair your tractor - the right parts. Our low prices and years of research make us your best choice when you need parts. Shop Online Today.

Copyright © 1997-2024 Yesterday's Tractor Co.

All Rights Reserved. Reproduction of any part of this website, including design and content, without written permission is strictly prohibited. Trade Marks and Trade Names contained and used in this Website are those of others, and are used in this Website in a descriptive sense to refer to the products of others. Use of this Web site constitutes acceptance of our User Agreement and Privacy Policy TRADEMARK DISCLAIMER: Tradenames and Trademarks referred to within Yesterday's Tractor Co. products and within the Yesterday's Tractor Co. websites are the property of their respective trademark holders. None of these trademark holders are affiliated with Yesterday's Tractor Co., our products, or our website nor are we sponsored by them. John Deere and its logos are the registered trademarks of the John Deere Corporation. Agco, Agco Allis, White, Massey Ferguson and their logos are the registered trademarks of AGCO Corporation. Case, Case-IH, Farmall, International Harvester, New Holland and their logos are registered trademarks of CNH Global N.V.

Yesterday's Tractors - Antique Tractor Headquarters

Website Accessibility Policy