I've been fighting with the miserable generator in my Allis Chalmers D17 long enough. I've done everything to try to keep that generator charging, and enough is enough. It's time to put in an alternator.

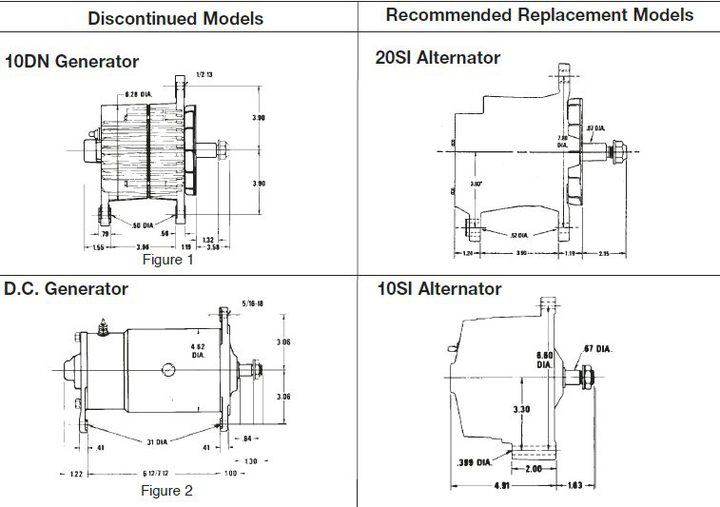

I have done a lot of reading up on this, and it seems the hardest part will be to make some brackets to mount it, and adjust it, and make a fan belt fit properly.

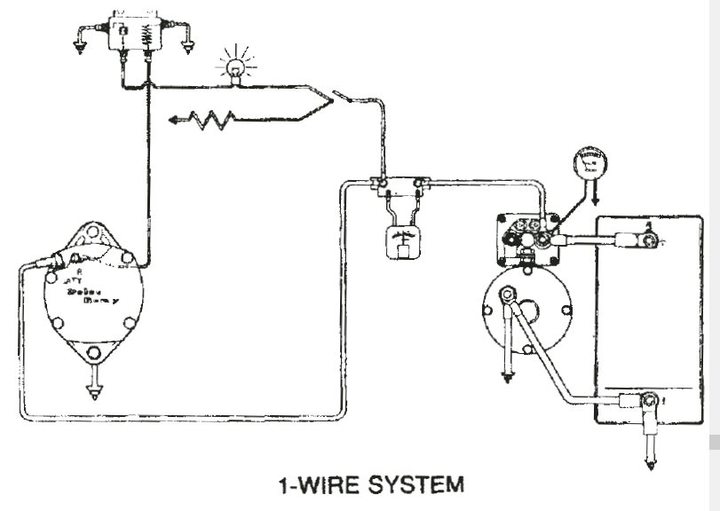

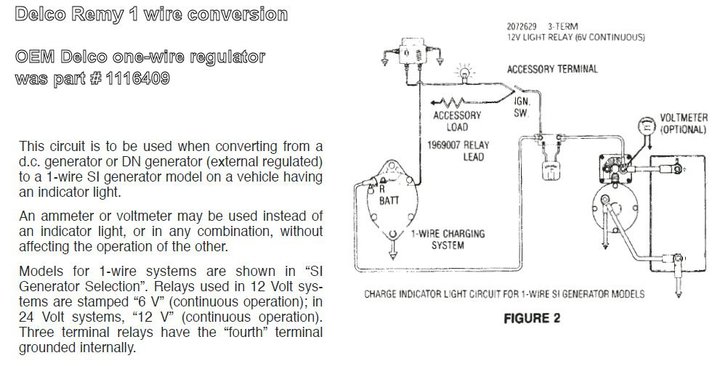

However, all this reading has me somewhat confused. First off, I learned to NOT use a ONE WIRE alternator. Not only are they very costly, but wont charge when the engine is running slow or idling. It appears that the only plus about them is that less wiring is needed. But running a few wires dont scare me any.

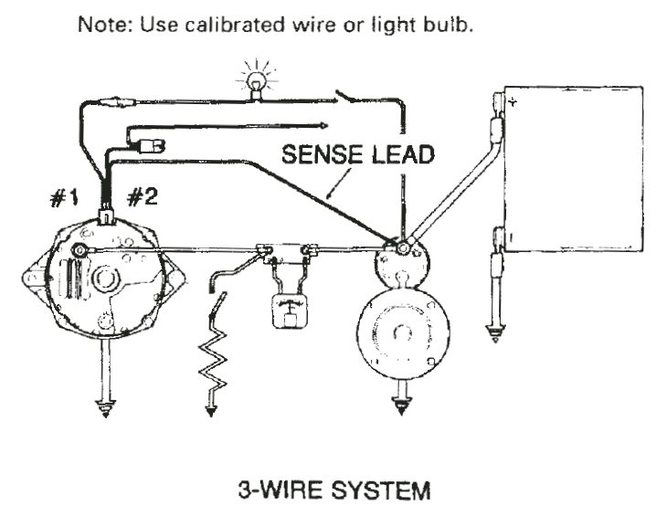

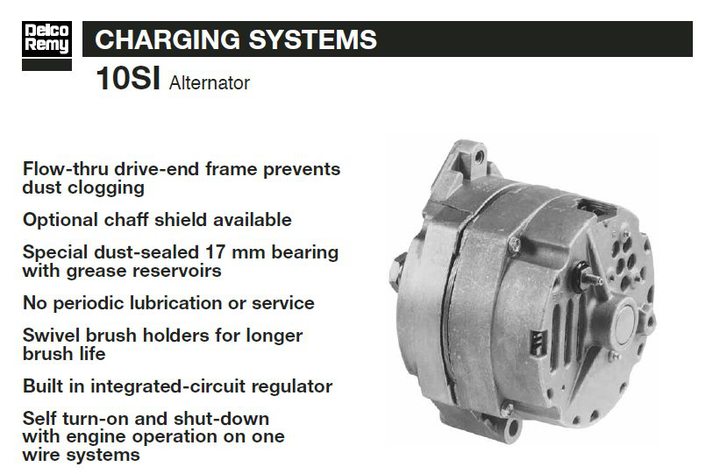

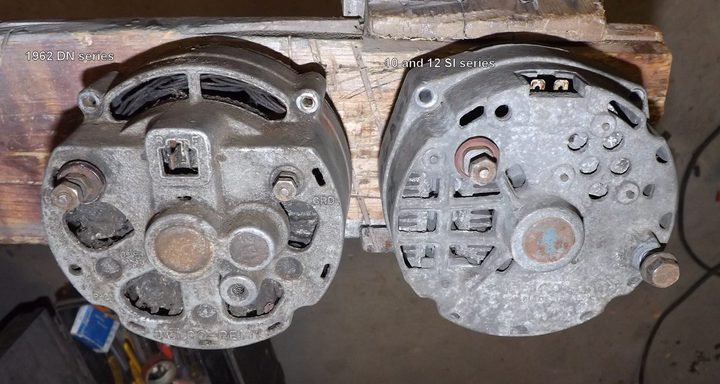

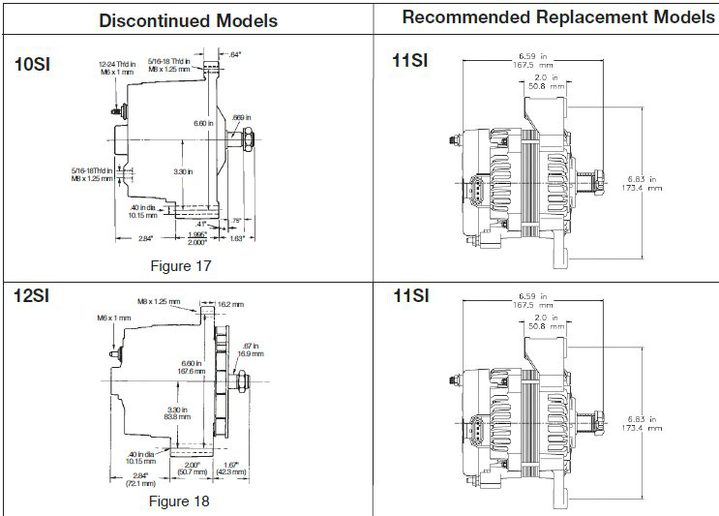

Anyhow, I already have several old GM alternators with the 3WIRE setup. So, that is what I will use. The alternator type recommended seems to be the 10Si. That is my first puzzle. None of the alternators that I have, have that number on them. But I wonder if that's more of a generic number for the TYPE, not the part number.

I have a GM 3wire alternator right next to me. It has the following numbers on it.

1100794 37A

8C25-12VNEG

I dont know what the first part means, but I assume the 37A means 37 amps. Also the 12V means 12 volts and the NEG means negative ground. (Is this correct?)

But is this then a 10Si?

It looks identical to some photos I have seen on the web for a 10Si.

Ok, so assuming this one will work, there is the THICK RED wire on the screw. Yea, I know that goes to the Battery. Then there is a plug with a blue and a white wire. I know one of these goes to the engine side of the ignition key switch. The other goes right back to the battery terminal and usually is just jumped back to that screw where the battery wire is connected. But which goes where? The white wire has a "R" stamped in the case, and the blue wire has a "F" stamped. (None of the websites mention that). So, which goes where?

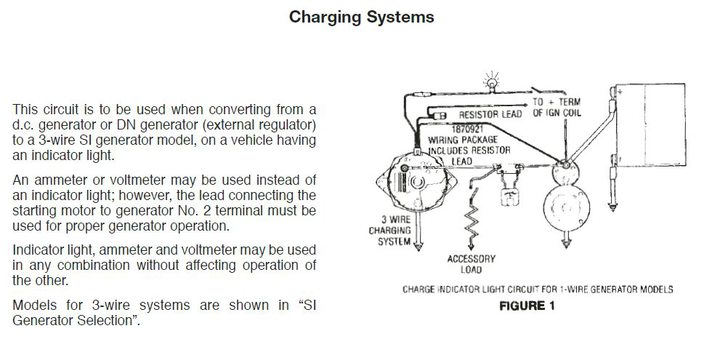

Also, I have seen that I need a diode in that wire that goes to the ignition switch. But others say to use a small lightbulb. WHICH IS IT? Or can I use either? (the diode seems easier).

However, if I use a diode, what amperage and voltage diode is required, or for that matter, if I use a lightbulb, what number bulb? (Yea, I am sure its a 12v bulb).

Other than that, I think I am ready to tackle this project, as soon as I get a diode and make sure this is the proper alternator.

Just so you know, this tractor is already 12V and although it came with a POS ground, I already changed it to a NEG ground by reversing the battery cables as well as reversing the wires on the Ammeter and on the Ignition coil.

One last thing. Someone told me I still need to have the alternator modified so it charges at low idle. Yet, others say that is only true on those ONE WIRE alternators.... Which is correct? And if I do need to modify the alternator, what part inside of it needs to be changed?

So many articles on the web, but none seem to get to the fine details or agree on the charging at idle. I do know the pulley on the alternator is a little smaller than the one on the generator. I suppose that can be changed, but wont a slightly smaller pulley make the alternator spin faster? (or do I have that backwards). If the alternator spins a little faster when the engine is at slow idle, I would think that would improve charging.

Thanks

I have done a lot of reading up on this, and it seems the hardest part will be to make some brackets to mount it, and adjust it, and make a fan belt fit properly.

However, all this reading has me somewhat confused. First off, I learned to NOT use a ONE WIRE alternator. Not only are they very costly, but wont charge when the engine is running slow or idling. It appears that the only plus about them is that less wiring is needed. But running a few wires dont scare me any.

Anyhow, I already have several old GM alternators with the 3WIRE setup. So, that is what I will use. The alternator type recommended seems to be the 10Si. That is my first puzzle. None of the alternators that I have, have that number on them. But I wonder if that's more of a generic number for the TYPE, not the part number.

I have a GM 3wire alternator right next to me. It has the following numbers on it.

1100794 37A

8C25-12VNEG

I dont know what the first part means, but I assume the 37A means 37 amps. Also the 12V means 12 volts and the NEG means negative ground. (Is this correct?)

But is this then a 10Si?

It looks identical to some photos I have seen on the web for a 10Si.

Ok, so assuming this one will work, there is the THICK RED wire on the screw. Yea, I know that goes to the Battery. Then there is a plug with a blue and a white wire. I know one of these goes to the engine side of the ignition key switch. The other goes right back to the battery terminal and usually is just jumped back to that screw where the battery wire is connected. But which goes where? The white wire has a "R" stamped in the case, and the blue wire has a "F" stamped. (None of the websites mention that). So, which goes where?

Also, I have seen that I need a diode in that wire that goes to the ignition switch. But others say to use a small lightbulb. WHICH IS IT? Or can I use either? (the diode seems easier).

However, if I use a diode, what amperage and voltage diode is required, or for that matter, if I use a lightbulb, what number bulb? (Yea, I am sure its a 12v bulb).

Other than that, I think I am ready to tackle this project, as soon as I get a diode and make sure this is the proper alternator.

Just so you know, this tractor is already 12V and although it came with a POS ground, I already changed it to a NEG ground by reversing the battery cables as well as reversing the wires on the Ammeter and on the Ignition coil.

One last thing. Someone told me I still need to have the alternator modified so it charges at low idle. Yet, others say that is only true on those ONE WIRE alternators.... Which is correct? And if I do need to modify the alternator, what part inside of it needs to be changed?

So many articles on the web, but none seem to get to the fine details or agree on the charging at idle. I do know the pulley on the alternator is a little smaller than the one on the generator. I suppose that can be changed, but wont a slightly smaller pulley make the alternator spin faster? (or do I have that backwards). If the alternator spins a little faster when the engine is at slow idle, I would think that would improve charging.

Thanks