super99

Well-known Member

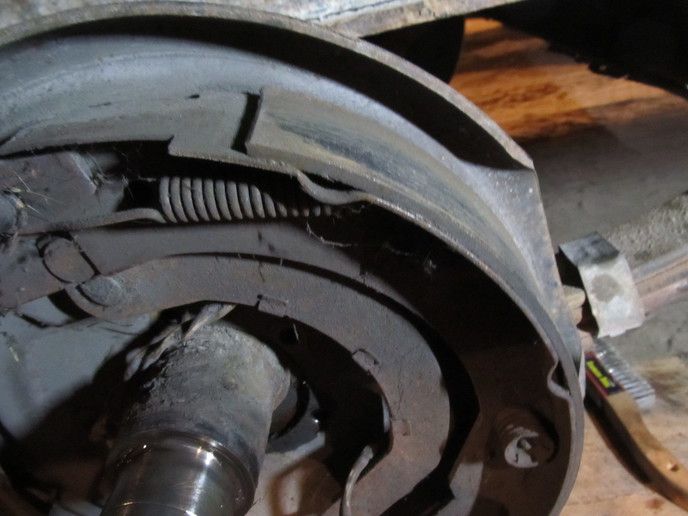

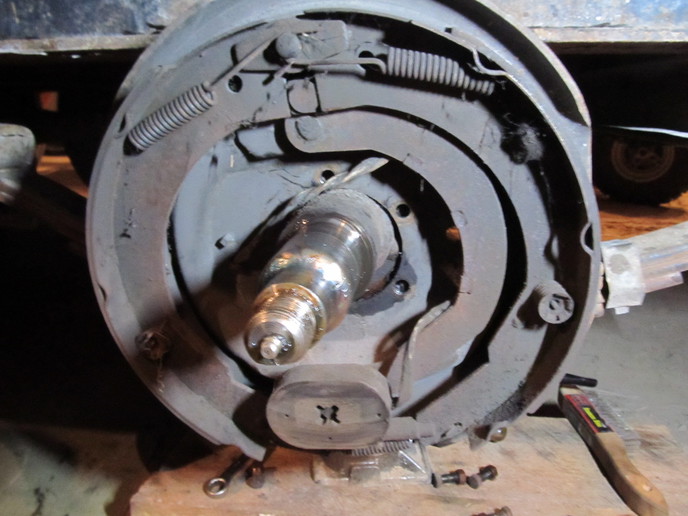

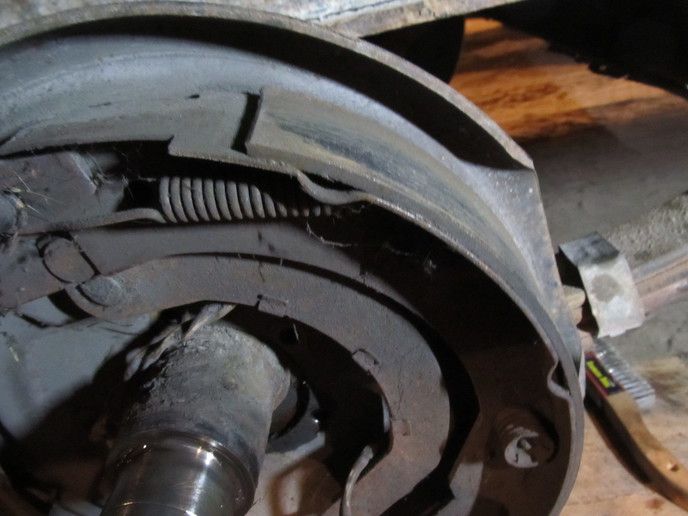

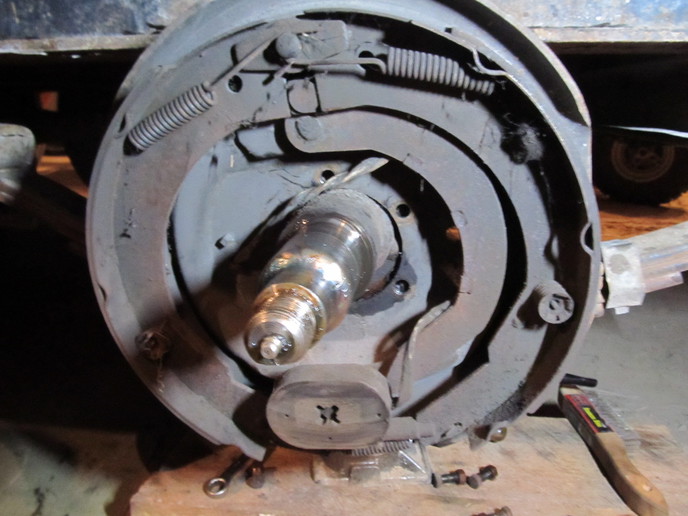

I bought a used P & J gooseneck 3 axle trailer. The brakes do not slow you down or stop the truck. You can hear the magnets make contact when the brakes are applied. I want to get them fixed before next weekend so I can take a tractor and plow to a plow day. I got the front tire and hub off the right side. It appears to me that there are no linings left, just metal to metal. I got the bolts out of the backer plate and want to take it to Mutual Wheel to get the right new parts. I can't find a connector in the wire running to the brakes. Wire from the magnet goes thru the backer plate, thru a hole in the frame and then runs towards the back of the trailer inside a metal tube. Is there a connector somewhere that I'm missing or do you add connector when the brakes are replaced?? Also, the arm that the magnet is attached to will not move. Shouldn't the arm move to move the shoes out against the drum?? Someone please explain this to me, I'm stumped. Thanks, Chris