Adirondack case guy

Well-known Member

Over the years my firewood harvesting equipment has evolved, from a simple 20" B&S 5HP splitter, to a mechanized firewood harvesting system. I like to leave a minimal "footprint" when I harvest wood.

I built a 3pt. skidding arch for my Kubota B2150. It manuvers among the trees and leaves little impact on the new growth. Pics show it's design. The blade pops of in a matter of seconds, and you can see the jaws and top link to fasten any CatI implement to it. I used to mount the splitter on the skidding arch on the Kubota, but I also had to remove it to mow the lawn., so I now have the splitter mounted on the 3pt hitch of my 431, which was just sitting in the barn. Now I can keep the belly mower on the Kubota and still get the splitter and elevator up to the landings in the woods.

The splitter when new back in mid 70s had two wheelbarrow wheels on the back and the bed of the splitter was less than a foot off the ground and had no catch trays on the sides. It killed your back if you stood and leaned over. Had to work on your knees.

First modification was to cut off the wheels and fab up struts to raise it up and add a front caster wheel and seat for the lever operator to sit on.

That was better, but still a bit hard on the back. I welded pins to the back of the splitter frame and a 3pt tower to mount it onto a tractor. Much better. I work it at waist heigth now, and the jib pole with 12V winch lifts heavy block onto the splitting bed. Built the side trays to keep blocks from falling off during the first split of bigger blocks. Another back saver.

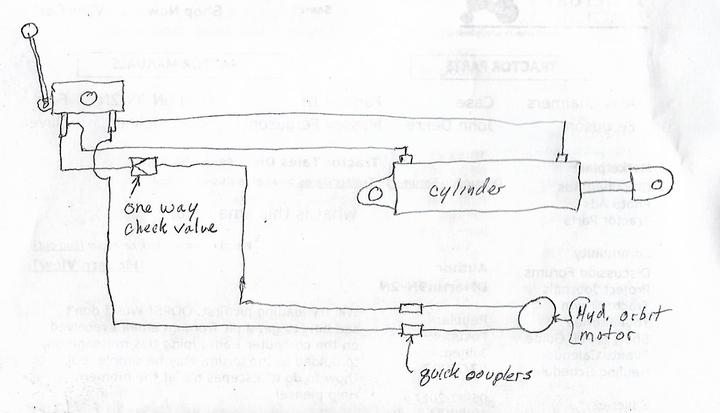

I thought it was rather stupid to lift blocks up onto the splitter, split them and watch them drop back to the ground and have to load split wood off the ground again, so I built the elevator to carry the split wood directly up into the trailer with no further bending and lifting. I still have a glitch, as I am stacking the top of the trailer loads, I built a bigger trailer last winter so I would not have to stack wood on it, but on a test trial the old 4x36"tilt cylinder blew out the top packings, and I have not yet gotten to a hyd. shop to buy new ones.

The elevator was a ground up fabrication. I had a hyd. motor and lots of 1" square and rectangular tubing from old Kubota shipping crates and a bunch of NOS galvanized sheet metal bottoms and covers from Jamesway silage conveyors.

Several have asked how I maintain even length of cut on all the wood. I mounted a piece of pex tubing on my saw handles to use as a guide. The tubing is flexible and doesn't bother even when felling trees.

I built a 3pt. skidding arch for my Kubota B2150. It manuvers among the trees and leaves little impact on the new growth. Pics show it's design. The blade pops of in a matter of seconds, and you can see the jaws and top link to fasten any CatI implement to it. I used to mount the splitter on the skidding arch on the Kubota, but I also had to remove it to mow the lawn., so I now have the splitter mounted on the 3pt hitch of my 431, which was just sitting in the barn. Now I can keep the belly mower on the Kubota and still get the splitter and elevator up to the landings in the woods.

The splitter when new back in mid 70s had two wheelbarrow wheels on the back and the bed of the splitter was less than a foot off the ground and had no catch trays on the sides. It killed your back if you stood and leaned over. Had to work on your knees.

First modification was to cut off the wheels and fab up struts to raise it up and add a front caster wheel and seat for the lever operator to sit on.

That was better, but still a bit hard on the back. I welded pins to the back of the splitter frame and a 3pt tower to mount it onto a tractor. Much better. I work it at waist heigth now, and the jib pole with 12V winch lifts heavy block onto the splitting bed. Built the side trays to keep blocks from falling off during the first split of bigger blocks. Another back saver.

I thought it was rather stupid to lift blocks up onto the splitter, split them and watch them drop back to the ground and have to load split wood off the ground again, so I built the elevator to carry the split wood directly up into the trailer with no further bending and lifting. I still have a glitch, as I am stacking the top of the trailer loads, I built a bigger trailer last winter so I would not have to stack wood on it, but on a test trial the old 4x36"tilt cylinder blew out the top packings, and I have not yet gotten to a hyd. shop to buy new ones.

The elevator was a ground up fabrication. I had a hyd. motor and lots of 1" square and rectangular tubing from old Kubota shipping crates and a bunch of NOS galvanized sheet metal bottoms and covers from Jamesway silage conveyors.

Several have asked how I maintain even length of cut on all the wood. I mounted a piece of pex tubing on my saw handles to use as a guide. The tubing is flexible and doesn't bother even when felling trees.