cumminspuller

Member

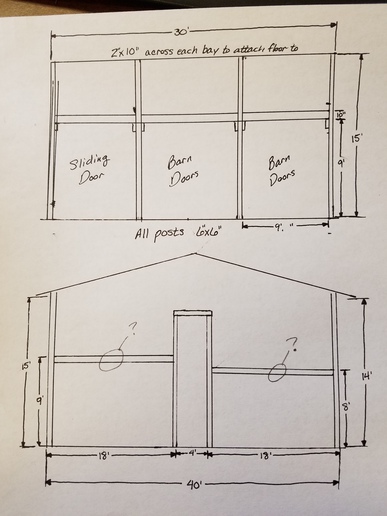

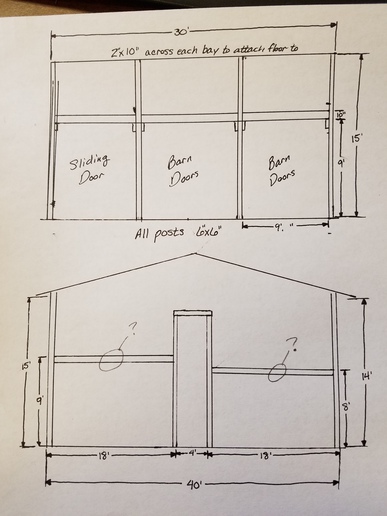

I'm planning on building a barn loft to store square bales in. I would like to keep the area underneath the loft as open as possible to help with space when it comes time to clean out. The part I am uncertain about is what to use for a support to stretch from the outside posts of the barn to the posts that will be in the middle of the barn. This span will be about 18 feet. I'd like to stay reasonable on the cost as possible but also use something that is going to last. I know I could hunt for several I-beans and that would do the job but be way out of the price range I'd like to be in. Whatever I use for this part will have 2x8's or 2x10's attached to it with the floor of the loft nailed to it. I would appreciate any help on this. I have attached a drawing to hopefully help explain what I'm needing to do. To keep this tractor related the other end of this barn is where I store some of my 2 cylinders and combine. Thanks Chris