Hi everyone,

So I recently helped start a 4-H tractor club and we are trying to have a little plow day type thing on friday with myself and a few of the kids in the club and FFA.

I am trying to figure out how much fuel the tractors will burn. I don't have that good of an idea since at fairs, they are running on and off and hardly at full throttle or under a heavy load.

The tractors I have that I am considering bringing are a 1937 F-12 (with overdrive), a Farmall H, or a John deere B. This will be with a 2 bottom plow, and a friend is bringing their JD A to pull the 3 bottom plow that I have. We have to drive maybe 2 miles down the road to the farm, and hoping to plow for maybe 2 hours. We figure just drive them since it is a pain to get them off the gooseneck trailer we have. From those who have done this before, about how much fuel do you burn per hour?

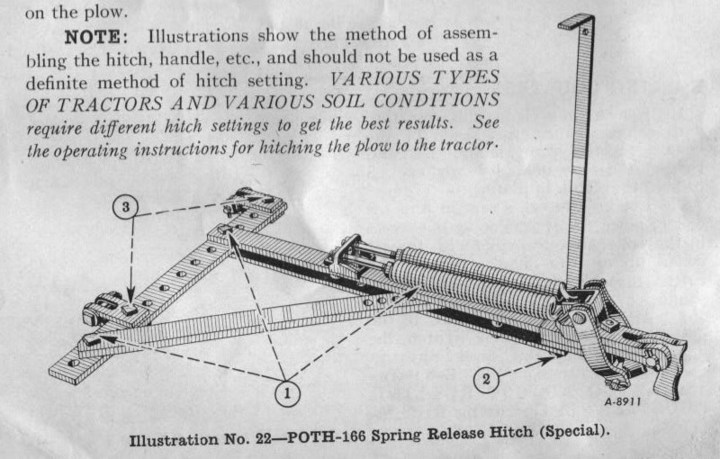

Also, is there anything that should be done to the plows in advance? I know I'll be greasing them, and one of them has had the quick release removed so not sure if I have time to fix that, and it is missing the bracket for one of the disks/coulters so one of them is not on the 3 bottom. Will either of those be a problem?

Any other advice is appreciated. I have little experience plowing, as the closest plow day is 2 hours away in New Hampshire with the New England IH chapter so I haven't tried to attend that one.

Thanks,

~FarmallCT

So I recently helped start a 4-H tractor club and we are trying to have a little plow day type thing on friday with myself and a few of the kids in the club and FFA.

I am trying to figure out how much fuel the tractors will burn. I don't have that good of an idea since at fairs, they are running on and off and hardly at full throttle or under a heavy load.

The tractors I have that I am considering bringing are a 1937 F-12 (with overdrive), a Farmall H, or a John deere B. This will be with a 2 bottom plow, and a friend is bringing their JD A to pull the 3 bottom plow that I have. We have to drive maybe 2 miles down the road to the farm, and hoping to plow for maybe 2 hours. We figure just drive them since it is a pain to get them off the gooseneck trailer we have. From those who have done this before, about how much fuel do you burn per hour?

Also, is there anything that should be done to the plows in advance? I know I'll be greasing them, and one of them has had the quick release removed so not sure if I have time to fix that, and it is missing the bracket for one of the disks/coulters so one of them is not on the 3 bottom. Will either of those be a problem?

Any other advice is appreciated. I have little experience plowing, as the closest plow day is 2 hours away in New Hampshire with the New England IH chapter so I haven't tried to attend that one.

Thanks,

~FarmallCT