I've been storing hay and some equipment in a couple of dome shelters. These are military grade shelters I bought a few years ago. Typically they are used with a heavy vinyl covering from the OEM, but since only the frames were available to buy, I have successfully used billboard signs. Work great and cheap! They are 20 ft wide X 30/32 ft long and 10 ft high - the 10 ft being the radius of the dome.

These domes are strong enough that one can cover them with metal roofing - which I plan to do.

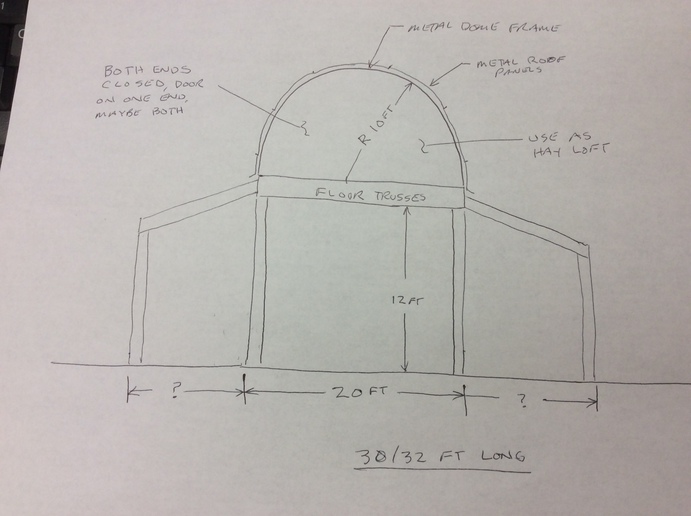

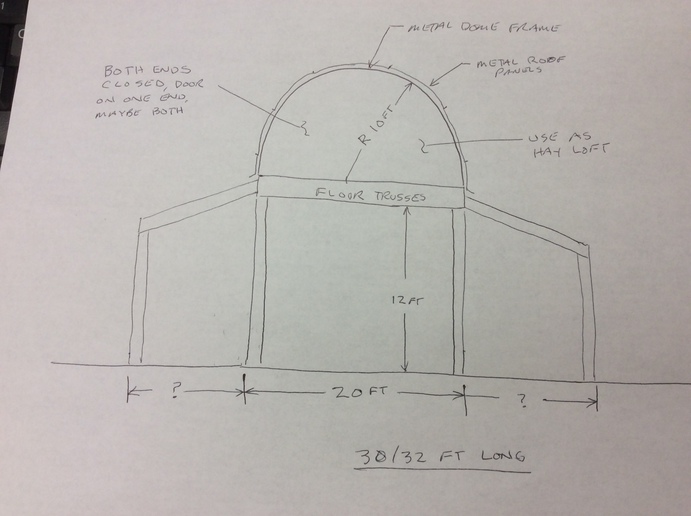

However, I'm toying with the idea of taking one of these shelters and making a pole barn - with a loft. The loft would be the original dome shelter setting on floor trusses. Off each side would be lean-to shelters. The pics show the shelter and barn sketch.

The question I have is what kind of pole support would you recommend, size, i.e. 4x4 or 6x6, etc down the middle section and then the sides? Spacing? Bracing? Floor truss recommendations? Lean-to width?

Hay in the loft - so,that loading would need to be accounted for too.

Not looking for a design that I'd tear off and start building, just some ideas.

Thanks,

Bill

These domes are strong enough that one can cover them with metal roofing - which I plan to do.

However, I'm toying with the idea of taking one of these shelters and making a pole barn - with a loft. The loft would be the original dome shelter setting on floor trusses. Off each side would be lean-to shelters. The pics show the shelter and barn sketch.

The question I have is what kind of pole support would you recommend, size, i.e. 4x4 or 6x6, etc down the middle section and then the sides? Spacing? Bracing? Floor truss recommendations? Lean-to width?

Hay in the loft - so,that loading would need to be accounted for too.

Not looking for a design that I'd tear off and start building, just some ideas.

Thanks,

Bill