You should upgrade or use an alternative browser.

- Thread starter vscummins

- Start date

Dune Country

Well-known Member

K Effective

Well-known Member

Moonlite37

Well-known Member

Andy Martin

Well-known Member

You can use a hanging scale and a cheater to measure torque as well. Just carefully measure from the point you hook the scale to on a cheater bar to the pivot on the breaker bar. A five foot cheater pulling 50# is 250 ft-lbs torque. If you use a scaffold so you can run the cheater straight up, all the load on the scale is the force on the cheater.

John Deere D

Well-known Member

What is the TORQUE Value (FT/LBS or INCH/LBS) you are concerned with?

Bob..

Janicholson

Well-known Member

Tom in TN

Well-known Member

- Location

- Southern Middle Tennessee

Can you make a video with a smart phone? I can't. I still have an old flip phone, but all of my children and grandchildren can make videos with their smart phones.

Tom in TN

Bob Harvey

Well-known Member

They measure in both directions.

Also you can hold the highest setting or set the value and it will alarm when it goes over.

Torque Adapter

guido

Well-known Member

Any wratchet type will do. Reverse torque will not prove overtourque.

Torque applied first accurately to a fastener, then marked and torqued againg with the faulty one, may be a better way to show it. Some kind of legal witness to the process would be a must! NO VIDEO EDITING,!!!!

Guido.

dr sportster

Well-known Member

Paul from MI

Well-known Member

Hobo,NC

Well-known Member

- Location

- Sanford, NC

That's good because as stated in a few post you would have your work cut out for you to prove it. I doubt many folks have the technology to prove it was over torqued.

can you use a torque wrench in reverse

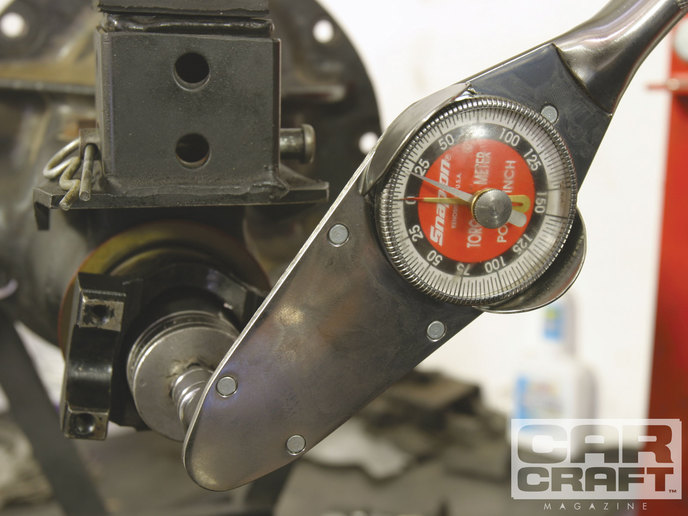

http://www.hotrod.com/how-to/additional-how-to/ctrp-1111-torque-wrench-myths/

Hobo,NC

Well-known Member

- Location

- Sanford, NC

(quoted from post at 10:08:44 01/22/16) Thanks for the advice guys I'm changing all the studs and lug nuts on the truck just for peace of mind I used some blue loctite on the ones I've already relppaced .

Did the nuts come loose are over torquing strip the threads. I have had a set of duels work loose on a F350. The customer picked up on it so no major damage. From that event on I always run the nuts up and manually go back over them with a bar and pipe...

I had the left front on a older F350 (left had thread) work loose on a test drive :shock: In a mater of a mile I picked up on the vibration. It amazed me how fast they worked there way off the stud. There were indications it has happen before the rims were of the split ring type he had planed on replacing the rims anyways that event put the process in motion...

I understand your frustration a loose wheel to me is ranked up high on my list of things that shame me. Other than one wheel all the others were a damaged wheel are the incorrect wheel but in all cases I should have caught it the show stopped till it was corrected.. :!: I don't see how one could legally wiggle out of a preexisting condition if was aware of it are had some indication something did not go back together correctly...

I see allot of cars come into the shop with a missing lug nut How the last guy let it roll out his door like its no big deal is beyond me "see preexisting condition"

Similar threads

- Replies

- 5

- Views

- 457

- Replies

- 2

- Views

- 190

- Replies

- 25

- Views

- 2K

We sell tractor parts! We have the parts you need to repair your tractor - the right parts. Our low prices and years of research make us your best choice when you need parts. Shop Online Today.

Copyright © 1997-2024 Yesterday's Tractor Co.

All Rights Reserved. Reproduction of any part of this website, including design and content, without written permission is strictly prohibited. Trade Marks and Trade Names contained and used in this Website are those of others, and are used in this Website in a descriptive sense to refer to the products of others. Use of this Web site constitutes acceptance of our User Agreement and Privacy Policy TRADEMARK DISCLAIMER: Tradenames and Trademarks referred to within Yesterday's Tractor Co. products and within the Yesterday's Tractor Co. websites are the property of their respective trademark holders. None of these trademark holders are affiliated with Yesterday's Tractor Co., our products, or our website nor are we sponsored by them. John Deere and its logos are the registered trademarks of the John Deere Corporation. Agco, Agco Allis, White, Massey Ferguson and their logos are the registered trademarks of AGCO Corporation. Case, Case-IH, Farmall, International Harvester, New Holland and their logos are registered trademarks of CNH Global N.V.

Yesterday's Tractors - Antique Tractor Headquarters

Website Accessibility Policy