When I bought my JD 5055d with the 2.9L - 3 cylinder engine I made it a point to work the engine during the first 100 hrs. Also had the dealer give it a dyno workout before delivery.

Friend of mine just bought a new Deere and he worked it hard for about 5 hrs and feels good to go.

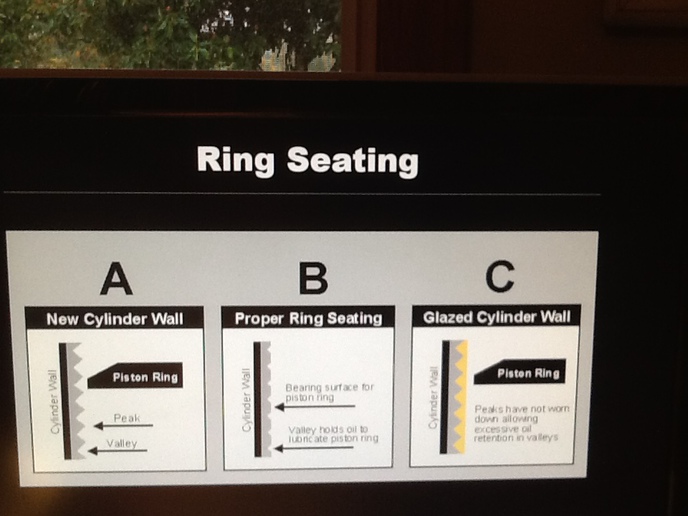

My question is - tell me about breaking-in a Diesel engine, new or say for a classic, like my MF50 or an IH 856 or a JD 4020 when the engine has been rebuilt? Are the rings basically seated instantly upon hard use - what are you getting over the first 100 hrs from the new or rebuilt engine and the break-in oil in it?

Is my buddy's tractor good to go - normal operation through the remainder of the break-in period or more heavy loads, like I did with my JD to the 100 hr mark and then a normal oil and filter change?

Thanks!

Bill

Friend of mine just bought a new Deere and he worked it hard for about 5 hrs and feels good to go.

My question is - tell me about breaking-in a Diesel engine, new or say for a classic, like my MF50 or an IH 856 or a JD 4020 when the engine has been rebuilt? Are the rings basically seated instantly upon hard use - what are you getting over the first 100 hrs from the new or rebuilt engine and the break-in oil in it?

Is my buddy's tractor good to go - normal operation through the remainder of the break-in period or more heavy loads, like I did with my JD to the 100 hr mark and then a normal oil and filter change?

Thanks!

Bill