steve terplak

Member

Hi guys,

I posted a couple days ago with an unknown PTO issue I encountered while baling small squares with a Landini Vision 105. This is a fairly modern tractor (2003) with electronic PTO. While baling , I suddenly was not turning the balers PTO shaft and making a clattering sound.

When not hooked up I turned the PTO on and off, but while off, I could spin it in both directions by hand, and it would not turn another shaft.

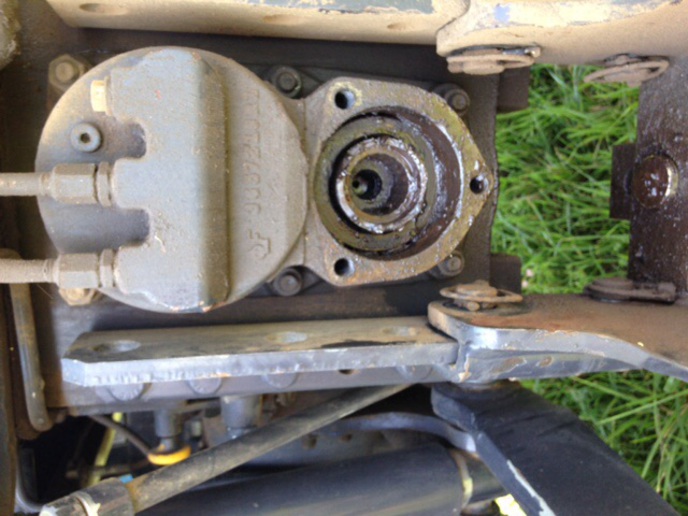

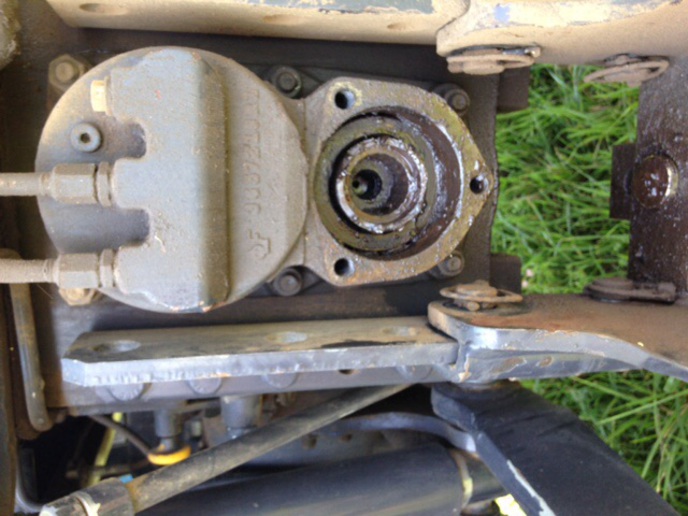

I removed the three bolts seen in picture 1 and found a broken shaft.

A few questions:

In the manual, there are pictures to replace the 540 shaft with a 1000 shaft. You remove the three exterior bolts and then that should expose four bolts around the shaft which, after unbolting, you remove the old shaft and put the new one on. I do not see these four bolts.

Are they behind the ring inside? Do I need to remove the entire unit? (in the pictures there are 6 bolts and two hydraulic lines).

Also, upon removing the three bolts which exposed the broken shaft, should the unit have been filled with hydrualic oil and a seal or anything?

Not sure if I am using the word shaft where I should be using stub, if so, I am sorry.

I know to many these are stupid, inherent, questions but I have an operator's manual but not repair manual for this tractor and I struggle to find anything decent online.

I hate to tear into anything before I know more about it.

This seems like a fairly straightforwards repair.

Also, this tractor is similar (I believe) to a McCormick 105, but not positive.

Thanks in advance for any info.

I posted a couple days ago with an unknown PTO issue I encountered while baling small squares with a Landini Vision 105. This is a fairly modern tractor (2003) with electronic PTO. While baling , I suddenly was not turning the balers PTO shaft and making a clattering sound.

When not hooked up I turned the PTO on and off, but while off, I could spin it in both directions by hand, and it would not turn another shaft.

I removed the three bolts seen in picture 1 and found a broken shaft.

A few questions:

In the manual, there are pictures to replace the 540 shaft with a 1000 shaft. You remove the three exterior bolts and then that should expose four bolts around the shaft which, after unbolting, you remove the old shaft and put the new one on. I do not see these four bolts.

Are they behind the ring inside? Do I need to remove the entire unit? (in the pictures there are 6 bolts and two hydraulic lines).

Also, upon removing the three bolts which exposed the broken shaft, should the unit have been filled with hydrualic oil and a seal or anything?

Not sure if I am using the word shaft where I should be using stub, if so, I am sorry.

I know to many these are stupid, inherent, questions but I have an operator's manual but not repair manual for this tractor and I struggle to find anything decent online.

I hate to tear into anything before I know more about it.

This seems like a fairly straightforwards repair.

Also, this tractor is similar (I believe) to a McCormick 105, but not positive.

Thanks in advance for any info.