Lou from Wi.

Well-known Member

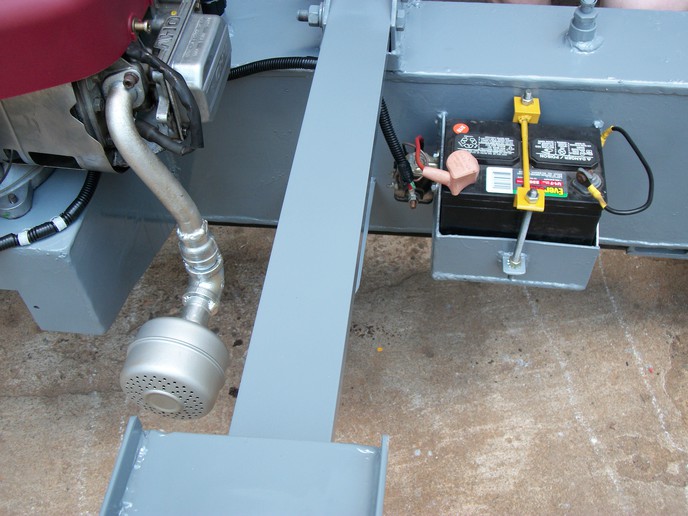

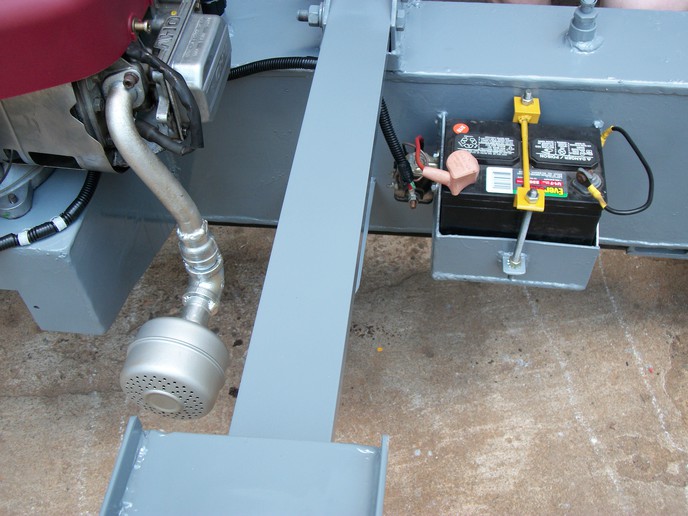

Now we are waiting on money for hydraulic cylinder, hoses, and hydraulic fittings, and hydraulic oil. Engine sure runs strong and good. I am anxious to see how it does on 10 cord of wood this year. Prices have gone way up since we done the first one,but still not what they are asking for factory new. This one also figures out to be 40-50 ton. Our first one has never failed us on any size or type of hardwood. Splitters are designed to save a lot of joint and muscle wear and tear. Will show more pictures when it is completed and running.

Regards,

Lou

Regards,

Lou