Lou from Wi.

Well-known Member

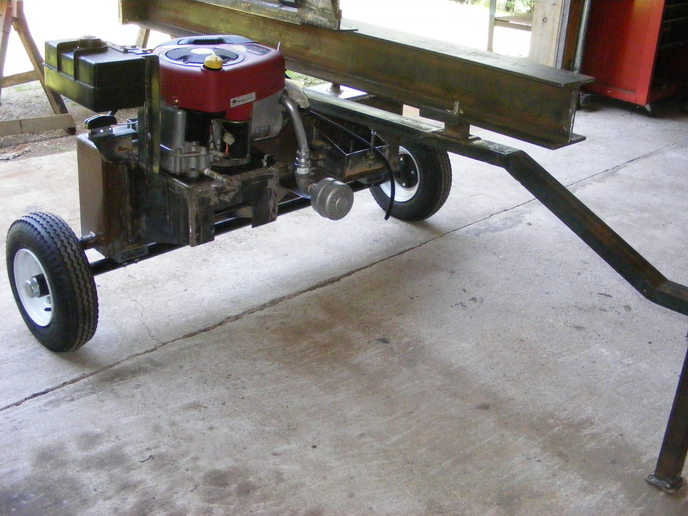

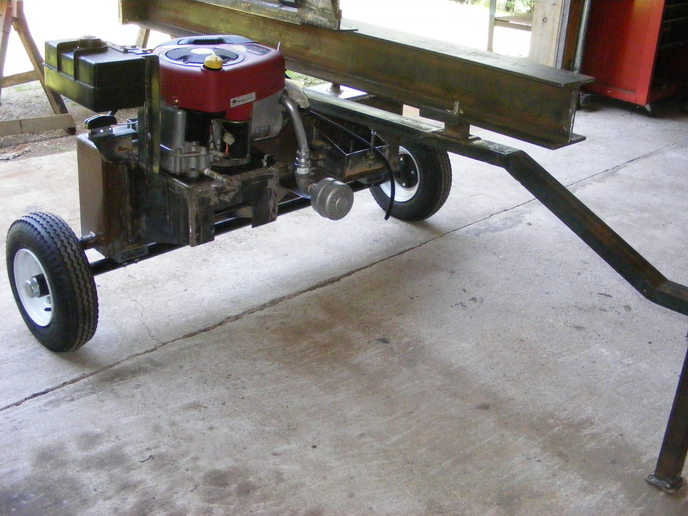

Coming right down the wire. Son added several more pieces to the puzzle, then it will be painted and ready to go to work. Daughter gets her wood delivered tomorrow,AM, so hopefully the new splitter will get its workout. Been taking a lot of time off due to hot humid weather 80- 90 degree day with rain. I really don't see how my son can keep up with everything, IE splitter, garden, lawn, etc.etc. Figuring when the log splitter is done, it should be in the neighborhood of costing ( a new one) around $2,000.00 to 2500.00, if we had to buy it new. Our cost is below 1/2 that for materials,not counting labor.

The motor came with a frame and a complete manual trans-axle,which we have no use for and will put up for sale. Not sure what lawn mower manufacturer it came from. If I was younger it would be on a go-cart,so I could go check the mail.Oh well. The case that says, better late than never, is better never than late . The guys on here who were contemplating building one, I say do it, they are quite a project,and a worthwhile one at that. The splitter saves a whole lot of problems with aching back and worn out joints. When we get it all finished we will show you the end result. Warmest regards,

LOU

The motor came with a frame and a complete manual trans-axle,which we have no use for and will put up for sale. Not sure what lawn mower manufacturer it came from. If I was younger it would be on a go-cart,so I could go check the mail.Oh well. The case that says, better late than never, is better never than late . The guys on here who were contemplating building one, I say do it, they are quite a project,and a worthwhile one at that. The splitter saves a whole lot of problems with aching back and worn out joints. When we get it all finished we will show you the end result. Warmest regards,

LOU