My nephew was given a 24' x 24' pole building. We have it most of the way down. I started wiggling one of the posts to see how well it was stuck in the ground and it snapped off. Very rotten. We went around and they all snapped off. The owner said the building is twelve years old.

When I was still building, treated was heavy, wet and very green. I have pulled posts that have been in the ground for years with no apparent deterioration. Is the modern treated that different or are there different grades of treated? I remember reading that the chemicals have been changed but this is unacceptable

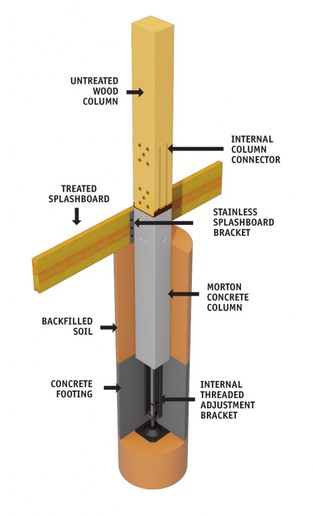

Kid is planning on putting it back up but doubling the size and using new siding on the front and the reclaimed on the sides and rear. We want something in the ground that will last.

Does anybody have knowledge on contemporary treated or replacement materials and/or methods?

Jay

When I was still building, treated was heavy, wet and very green. I have pulled posts that have been in the ground for years with no apparent deterioration. Is the modern treated that different or are there different grades of treated? I remember reading that the chemicals have been changed but this is unacceptable

Kid is planning on putting it back up but doubling the size and using new siding on the front and the reclaimed on the sides and rear. We want something in the ground that will last.

Does anybody have knowledge on contemporary treated or replacement materials and/or methods?

Jay