john in la

Well-known Member

Thinking about building a pole shed as the termites; weather; rot; has about made my current shed non useable.

Something in the 24 or 28ft squared size.

In the drawing planning stage right now trying to decide how I want this done before I go talk to parish inspector or a engineer.

This will be a self build not a kit.

Need at least 110 mph wind load

0 snow load or very little to cover rain water

Dirt floor as I have about 40 yards of 4x4 pavers to use as a floor.

Where I am at is trying to decide what covering to use for the walls and roof.

For the walls SmartSide Composite Panel with a 50yr warranty

http://www.homedepot.com/p/SmartSide-96-in-Composite-Panel-27874/100055901?N=bb0x#

and Classic Rib Steel Roof Panel with a 45yr paint warrant for the same price per square foot so I am leaning to steel.

http://www.homedepot.com/p/Unbrande...eel-Roof-Panel-in-Charcoal-2313217/204254778#

But for the roof it is a totally different animal. I do not want just steel because of condensation in my very humid area and the noise of rain beating on a steel roof.

3 tab shingles over osb would be my #1 choice but would require double the amount of trusses (2ft o/c) as tin.

Started thinking about steel roof panels over osb but the 29ga steel only weighs 0.08 lbs less than the 3 tab shingles per square foot so we are back to a shingle roof.

I guess my next step is to ask a truss company about trusses 4ft o/c that will carry the weight of a shingle roof or just bite the bullet and go 2ft o/c. At $100 each that adds cost quick.

Your comments advise are welcome.

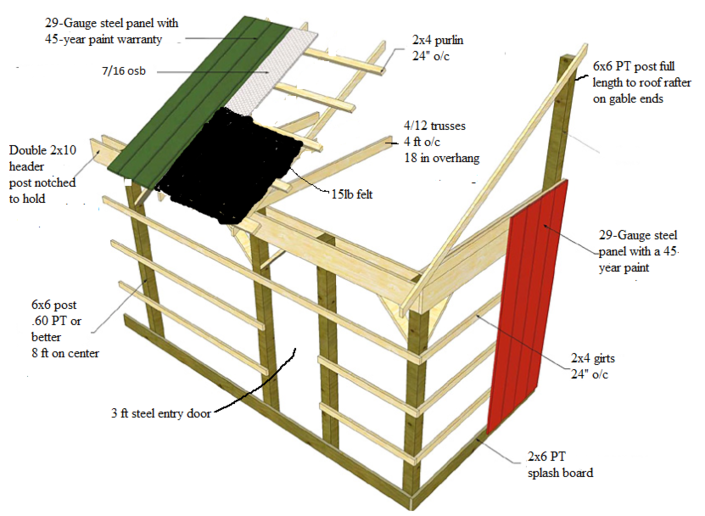

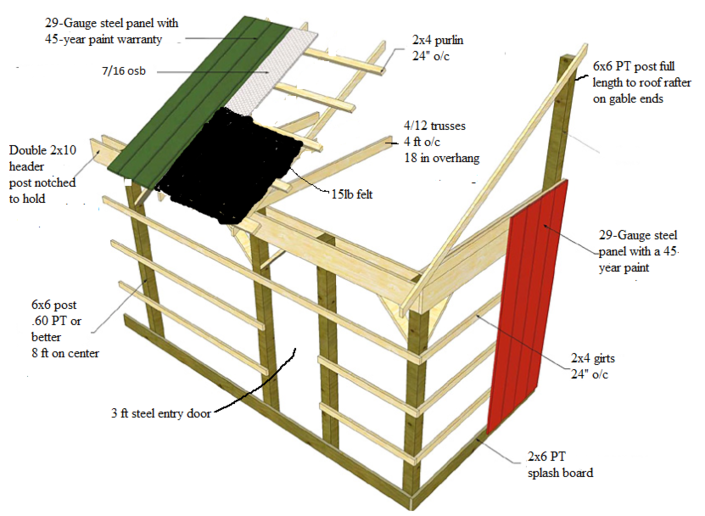

Here is a very preliminary drawing.

Something in the 24 or 28ft squared size.

In the drawing planning stage right now trying to decide how I want this done before I go talk to parish inspector or a engineer.

This will be a self build not a kit.

Need at least 110 mph wind load

0 snow load or very little to cover rain water

Dirt floor as I have about 40 yards of 4x4 pavers to use as a floor.

Where I am at is trying to decide what covering to use for the walls and roof.

For the walls SmartSide Composite Panel with a 50yr warranty

http://www.homedepot.com/p/SmartSide-96-in-Composite-Panel-27874/100055901?N=bb0x#

and Classic Rib Steel Roof Panel with a 45yr paint warrant for the same price per square foot so I am leaning to steel.

http://www.homedepot.com/p/Unbrande...eel-Roof-Panel-in-Charcoal-2313217/204254778#

But for the roof it is a totally different animal. I do not want just steel because of condensation in my very humid area and the noise of rain beating on a steel roof.

3 tab shingles over osb would be my #1 choice but would require double the amount of trusses (2ft o/c) as tin.

Started thinking about steel roof panels over osb but the 29ga steel only weighs 0.08 lbs less than the 3 tab shingles per square foot so we are back to a shingle roof.

I guess my next step is to ask a truss company about trusses 4ft o/c that will carry the weight of a shingle roof or just bite the bullet and go 2ft o/c. At $100 each that adds cost quick.

Your comments advise are welcome.

Here is a very preliminary drawing.