(quoted from post at 11:18:33 12/08/13) I have NEVER had any luck on a stuck motor that had that much water in it. The cylinder side walls will be pitted and the valve seats too. Plus the rings will be stuck in the piston walls too.

You are screwing around with ATF and whatever for 3-4 MONTHS. A head gasket set is only $58.01 on this site.

So STOP wasting time and effort. Just pull the head off. You can then see what is really wrong with the motor. Even if you get it to turn over it will either burn oil or be a hard starting motor with low compression caused by stuck rings or bad valve seats.

I know several guys on here tell you about all kinds of stuck motors they have gotten going with soaking with miracle oils mixes they use on those motors. In my 60 plus years I have seen maybe 1 or 2 motors that where gotten running with those treatments. 100% of those motors where not stuck with cylinders full of water.

THINK about how the cylinder wall will look with rust on them top to bottom??? Pull the head off. You still may not need to spend BIG money. The piston can be knocked down into the block some, unless it is all the way down. Then take a cylinder hone and clean the cylinder bore up. You may still have some pits that will hold some oil but you will not have the ridges of rust to catch the rings. The valves can be removed. Keep them in the order they come out of the head. Then take a wire brush on a drill and clean the rust out of the valve seat area. Use a wire brush on a grinder to clean the valves themselves. Then if the valve seats are not too pitted you can lap them with the valve from that seat. When you have cleaned things up and the motor turns freely then reassemble and adjust your valves and you should have a motor that will run fairly well IF the rings are not stuck too bad.

IF you really want to go into it "right" then drop the pan off when you have the head off. remove the pistons completely and check the rings out. If they look bad/stuck but the bores are pretty good then replaces the rings and reassemble.

So with less than $75 in a gasket set with shipping and a few evenings of work you can have the engine going if you have any luck at all.

IF it is rusted up badly then you will know you need to do more serious work on the motor or find a replacement.

This is just my 2 cents worth. I dislike halfa$$ "repairs". Also if you can't afford a $58 gasket set then you should think about if you can afford a tractor period.

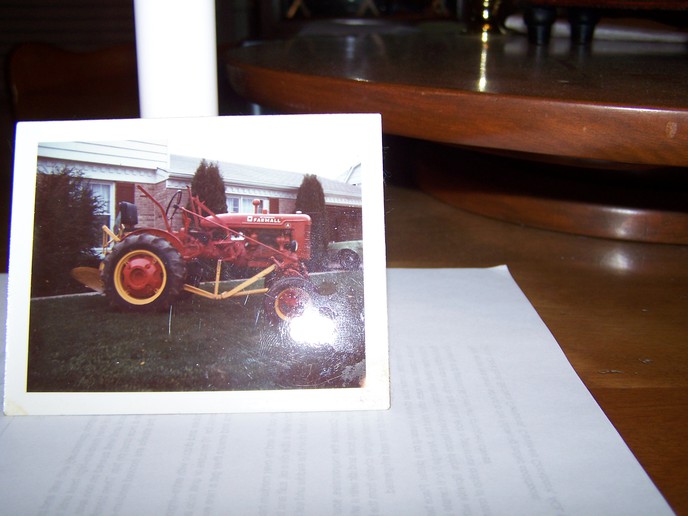

YT Farmall 460 head gasket set.