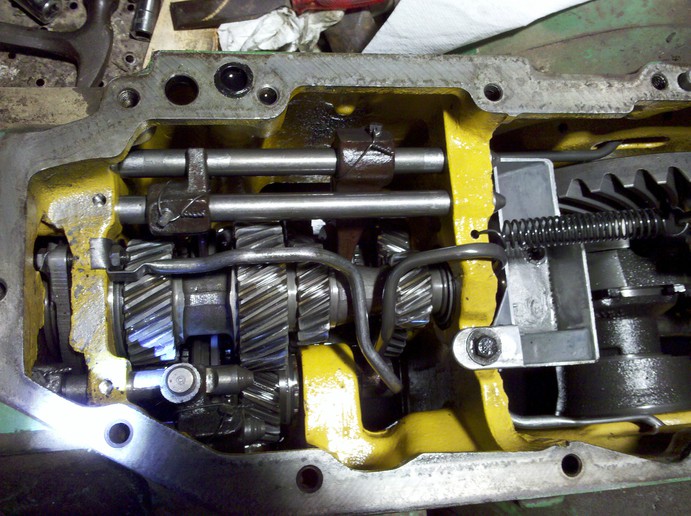

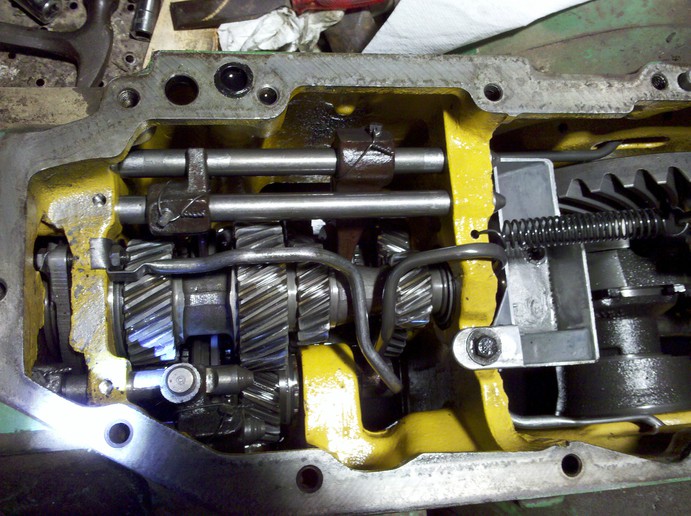

I was up at their place last night, he had the top cover off, and I forwarded what you posted, and reiterated this with him, all of which makes sense. He does know that the pto shaft needs to come out to get a better view from the end through the bore in the casting, but elected to take the top cover/rock shaft off first for some reason. In the 2nd photo where the LED light is concentrated is where I can see a brownish/rust colored tab move when the lever is moved, shaft does not connect to the rear, and only the rear spins, front shaft does not move. You can just see the splines in the photo.

I will say that its crowded in there LOL !

Question I have is, I suspect the shift collar, as the control lever linkage is intact, I had him spin the shaft while I moved the lever and used a focused LED light and I could see a brown, maybe slightly rusted tab, move back and forth down under the gears and shafts up top, it is difficult to see, but it sort of appears there is no collar, or possibly its destructed itself ? I looked from both vantage points, and it would appear if it were intact, you should be able to see it, and when that lever is moved it should move that collar as shown in the diagram over the rear shaft connecting the two. I was just wondering what you would think given the above.

The photo above you can't see much below, but in this aluminum looking sump under a spring, there was a table spoon or more of metal fines, it looked like anti-seize, but a magnet picks it up. I am wondering what bearing or what could be suspected, this I don't like, tells me there is a serious problem or will be. I did hear a pump whine with this tractor and that does appear to be part of the hydraulics, possibly the pump ?

With the top cover off, I see what you said about those other parts, best to replace as you said.

I don't believe his book is all that good, I think he definitely needs one like you suggested, given the condition of tractor and the shop I have tried to suggest to these people, go and put 2k or a tad more into her, get it all out on the table, pto, hydraulic pump, they've not fixed the charging system, run it off battery, its idiotic, but no insult to them, good friends and family, I just hate dealing with them on this, the mentality about keeping something in good repair differs, I don't budge on that, tell them bluntly, this time he's got no choice, so I said, take it to the shop, they exclusively work on older equipment that is constantly in use on all the farms nearby, we are fortunate to have such a business, not something you find often today, reasonable and top notch work, honest and hard working folks that do the right job from a garden tractor to a large piece of equipment, I would send anything I own to them, and I am a bit fussy!

I thank you for the help you provided in the earlier post, I am more curious about the mechanical issue here as something to learn, likely it will get sent out for repairs, and hopefully be done, she's not all that pretty but with some money spent now, she will last for years, its a pretty darned good tractor.

I will say that its crowded in there LOL !

Question I have is, I suspect the shift collar, as the control lever linkage is intact, I had him spin the shaft while I moved the lever and used a focused LED light and I could see a brown, maybe slightly rusted tab, move back and forth down under the gears and shafts up top, it is difficult to see, but it sort of appears there is no collar, or possibly its destructed itself ? I looked from both vantage points, and it would appear if it were intact, you should be able to see it, and when that lever is moved it should move that collar as shown in the diagram over the rear shaft connecting the two. I was just wondering what you would think given the above.

The photo above you can't see much below, but in this aluminum looking sump under a spring, there was a table spoon or more of metal fines, it looked like anti-seize, but a magnet picks it up. I am wondering what bearing or what could be suspected, this I don't like, tells me there is a serious problem or will be. I did hear a pump whine with this tractor and that does appear to be part of the hydraulics, possibly the pump ?

With the top cover off, I see what you said about those other parts, best to replace as you said.

I don't believe his book is all that good, I think he definitely needs one like you suggested, given the condition of tractor and the shop I have tried to suggest to these people, go and put 2k or a tad more into her, get it all out on the table, pto, hydraulic pump, they've not fixed the charging system, run it off battery, its idiotic, but no insult to them, good friends and family, I just hate dealing with them on this, the mentality about keeping something in good repair differs, I don't budge on that, tell them bluntly, this time he's got no choice, so I said, take it to the shop, they exclusively work on older equipment that is constantly in use on all the farms nearby, we are fortunate to have such a business, not something you find often today, reasonable and top notch work, honest and hard working folks that do the right job from a garden tractor to a large piece of equipment, I would send anything I own to them, and I am a bit fussy!

I thank you for the help you provided in the earlier post, I am more curious about the mechanical issue here as something to learn, likely it will get sent out for repairs, and hopefully be done, she's not all that pretty but with some money spent now, she will last for years, its a pretty darned good tractor.